Structure, assembly process, assembly line, test line and packaging line of wall-hung boiler

Wall-hung-boiler production is now highly modular and automated. Aluminum-extruded heat exchangers are bolted, not welded, to stop corrosion. Sheet-metal casings are punched, bent and sealed; burners, pumps and controls are then added on flexible conveyors with robot screw-drivers and AGV feeds. After auto-flip leak, electrical and combustion tests, a packaging line forms cartons, robot-loads each heater with locating foams, seals, straps and palletizes in 40 s, cutting staff from 15 to 1 and giving the industry a safe, repeatable, high-output model.

✅ 1. Structural Design of Wall-Hung Boilers

- Modular architecture: Heat exchangers are mainly extruded from aluminum and joined by bolts, eliminating weld-induced stress-corrosion.

- Sealing concept: Front/rear covers use O-rings plus screws to guarantee gas- and water-tightness.

- Heat-transfer optimization: Symmetrical fin packs and corrugated enhancement surfaces raise efficiency while limiting condensate corrosion.

✅ 2. Assembly Process

- Material preparation: High-temp, corrosion-resistant aluminum alloys, stainless steel and copper.

- Sheet-metal work: Shearing, bending, punching, welding and other steps form the casing.

- Internal build-up: Burner, heat exchanger, pump, control board, etc. are mounted in sequence; every joint is verified.

- Welding & sealing: Critical points are welded and then sealed with elastic adhesives to prevent gas or water leakage.

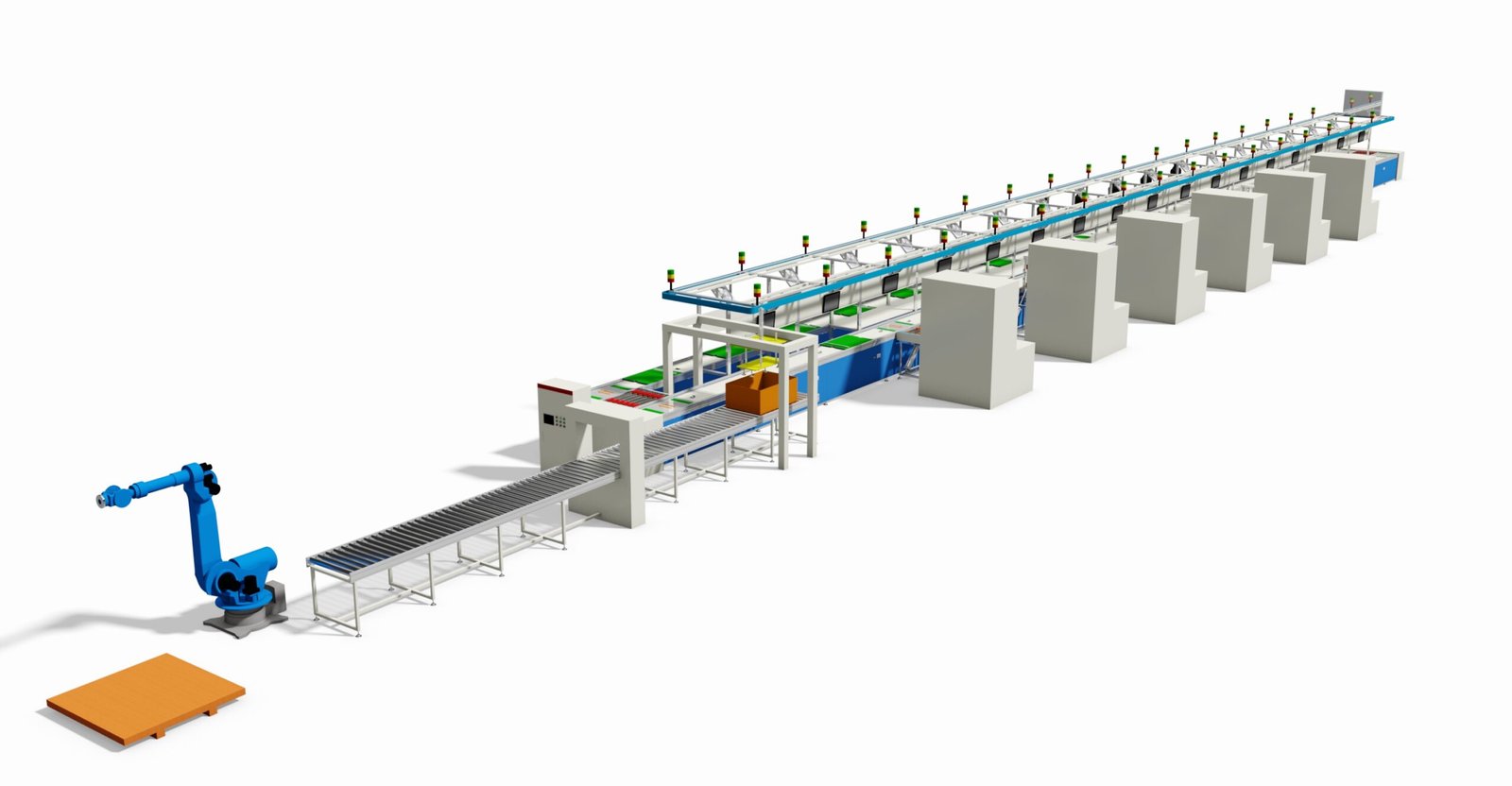

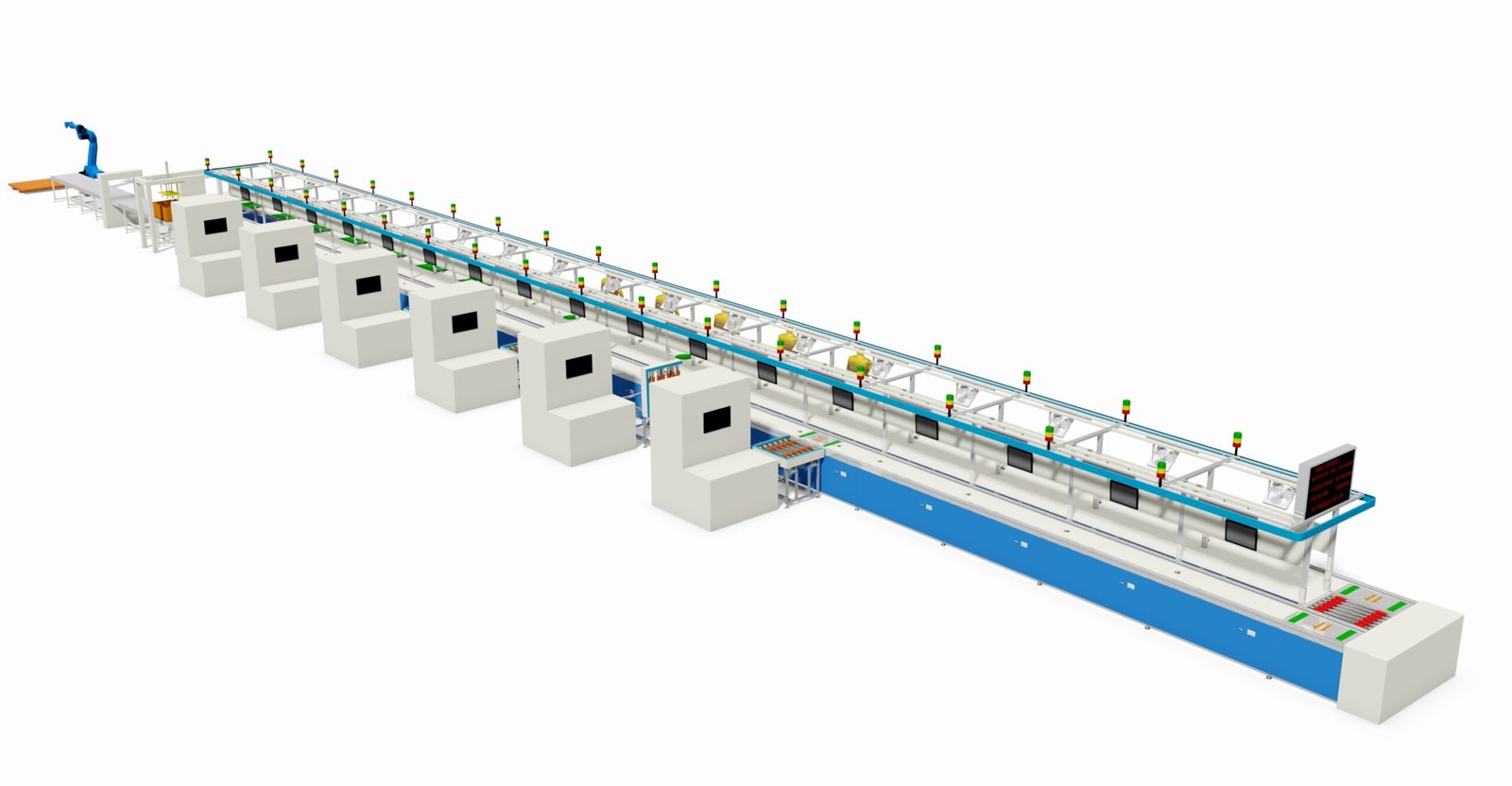

✅ 3. Assembly Line

- Conveyor layout: Straight, curved, lifting and lowering sections create a flexible line.

- Automation level: Robot screw-driving, AGV material supply, auto lift-&-rotate fixtures, etc. secure both speed and accuracy.

- Station configuration: Powered zones, stop gates, repair return loop, jigs, transfer units support takt-time production.

✅ 4. Test Line

- Auto flip & clamp: Finished boilers are flipped upright and fixed automatically; gas and water hoses are connected for testing.

- Test items:

– Flame leakage check (automatic gas sampling)

– Electrical & gas-tightness test

– Functional test (ignition, temperature control, safety shutdowns) - Safety feature: The flipper will not lower until test hoses are removed, avoiding accidental drops.

✅ 5. Packaging Line

- Automatic packaging sequence:

– Case erecting: Automatic carton former

– Packing: Robot or gripper places the boiler into the carton; foam blocks are fed automatically

– Sealing: Auto flap-folder and case sealer close top & bottom

– Strapping: Automatic banding machine applies PP/PET straps

– Palletizing: Robot stacks cartons on pallet—fully unmanned - Key difficulties & countermeasures:

– Boilers are front-heavy; special grippers and locating foams prevent tilting and impact

– Foams are pocket-milled and ribbed to protect bottom parts and cut material usage - Efficiency gain: Head-count reduced from 15 to 1; packing time cut to ≈ 40 s per unit.

✅ Overall Summary

Wall-hung-boiler manufacturing is now highly automated and modular. From structural design to final packaging, every step stresses safety, efficiency and repeatability. Automatic flip test rigs, robotic packing and unmanned palletizing especially lower labor costs and boost throughput, offering the industry a replicable high-productivity model.