Elevator logistics system,Continuous Vertical Conveyor

Continuous Vertical Conveyor (CVC)

Continuous Vertical Lifting Solution

High-Efficiency Vertical Material Handling · Seamless Multi-Floor Logistics Connection

I. Product Overview

The Continuous Vertical Conveyor (CVC) is a high-efficiency, continuous vertical material handling equipment that enables uninterrupted automatic transportation of goods between multiple floors through circularly running carriers (pallets/chains). Unlike reciprocating vertical conveyors that operate intermittently, the CVC achieves continuous material flow, significantly improving logistics efficiency.

II. Core Structural Features

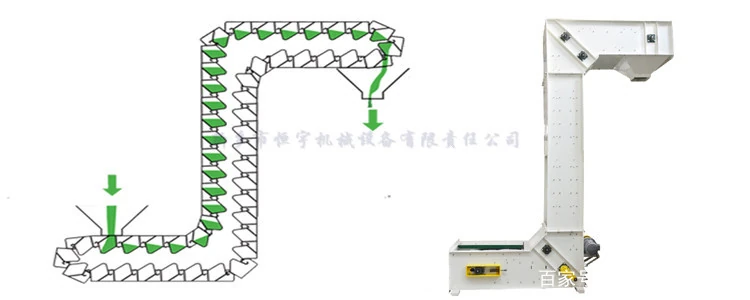

2.1 Z-Type/C-Type Layout Design

- Z-Type Layout: Suitable for scenarios with opposite inlet/outlet directions, offering high space utilization

- C-Type Layout: Suitable for same-direction inlet/outlet configurations, facilitating linear production line arrangement

- Customizable Height: Lifting height range from 2-30 meters, unlimited number of floors

- Modular Design: Quick installation and easy expansion

2.2 Key Component Structure

| Component | Technical Features | Material/Brand |

|---|---|---|

| Circular Conveyor Chain | High-strength alloy steel, wear-resistant lifespan >5 years | Germany IWIS / Japan Tsubaki |

| Carrier Pallet | Anti-slip surface, positioning accuracy ±1mm | Aluminum alloy / Carbon steel with powder coating |

| Drive System | Variable frequency speed control, soft start protection | SEW / NORD geared motors |

| Control System | PLC + Touch screen, MES integration supported | Siemens / Mitsubishi |

III. Technical Specifications

| Technical Parameter | Standard Specification | Optional Configuration |

|---|---|---|

| Max. Lifting Height | 2-30 meters | Customizable for greater heights |

| Conveying Speed | 10-30 m/min (Variable frequency adjustable) | Max. 60 m/min |

| Rated Load | 50kg/pallet (Standard) | Max. 200kg/pallet |

| Pallet Size | 600×400mm (Standard) | Customized per requirements |

| Conveying Cycle | Continuous conveying, no cycle limitation | – |

| Inlet/Outlet Direction | Single-in single-out / Single-in multi-out / Multi-in multi-out | Flexible combination |

| Power Supply | 3-15kW (depending on height and load) | – |

| Equipment Noise | ≤70dB | Low-noise type ≤65dB |

IV. Core Advantages

🚀 High-Efficiency Continuous Conveying

- No Waiting Time: Materials enter continuously without waiting for carriage reciprocation

- High Throughput: 1,000-3,000 pieces/hour (depending on material size)

- 24/7 Operation: Suitable for continuous automated production line operations

🛡️ High Safety Design

- Fully Enclosed Safety Guard: Compliant with CE safety standards, preventing personnel access

- Multiple Safety Devices: Upper/lower limit switches, anti-fall devices, emergency stop

- Door Interlock: Safety doors at inlets/outlets interlocked with equipment operation

- Fault Self-Diagnosis: PLC automatically detects abnormalities and alarms for shutdown

🔄 Intelligent Integration

- Seamless Connection: Automatic interfacing with roller conveyors, belt conveyors, and robotic arms

- Barcode/RFID Recognition: Automatic material identification and intelligent sorting

- MES/WMS System Integration: Real-time operation data upload, remote monitoring supported

- Variable Frequency Energy Saving: Automatic power adjustment based on load, 30% energy saving

V. Typical Application Scenarios

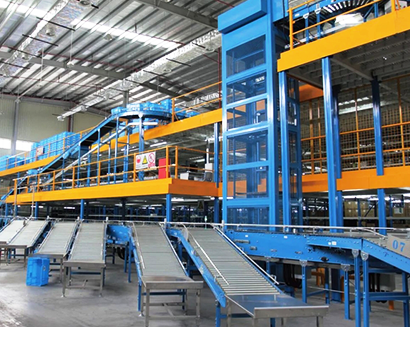

5.1 E-Commerce Logistics Centers

- Application: Cross-floor sorting and conveying of express parcels

- Advantage: Handling peak promotion periods with continuous operation without congestion

- Case Study: After deployment in an e-commerce warehouse, sorting efficiency increased by 150%

5.2 Manufacturing Production Lines

- Application: Flow of raw materials, semi-finished products, and finished goods between multi-floor factories

- Advantage: Reduces manual handling, achieves JIT (Just-In-Time) production

- Applicable Industries: Automotive parts, electronics manufacturing, pharmaceuticals, food & beverage

5.3 Warehousing & Distribution Centers

- Application: Vertical connection between mezzanine racks, AS/RS systems and picking zones

- Advantage: Maximizes vertical space utilization, improves storage density

- Configuration: Often integrated with shuttle systems and stacker cranes to form automated warehousing systems

VI. Comparison with Reciprocating Vertical Conveyor

| Comparison Item | Continuous Vertical Conveyor | Reciprocating Vertical Conveyor |

|---|---|---|

| Conveying Method | Continuous circulation, uninterrupted | Carriage reciprocation, intermittent |

| Conveying Efficiency | ⭐⭐⭐⭐⭐ Extremely High (1,000-3,000 pcs/hr) | ⭐⭐⭐ Medium (100-300 pcs/hr) |

| Suitable Materials | Small-medium items, regular packaging | Large items, heavy loads, palletized goods |

| Footprint | Compact (vertical layout) | Larger (requires carriage space) |

| Investment Cost | Medium | Lower |

| Recommended Scenario | High-frequency, high-volume conveying | Low-frequency, heavy-load conveying |

VII. Selection Guide

Key Factors to Consider for Selection:

- Material Characteristics

- Unit weight, dimensions (L×W×H)

- Packaging format (cartons, plastic totes, pallets)

- Surface characteristics (fragility, anti-slip requirements)

- Conveying Requirements

- Hourly throughput (pieces/hour)

- Lifting height, number of floors

- Inlet/outlet position relationship (Z-type/C-type/Linear)

- Environmental Conditions

- Ambient temperature (ambient/low-temperature cold storage/high-temperature)

- Cleanliness requirements (standard/food-grade/pharmaceutical-grade)

- Explosion-proof requirements (chemical industry)

- System Integration

- Upstream and downstream conveying equipment types

- Whether sorting and buffering functions are required

- Information system integration requirements (MES/WMS/ERP)

VIII. Contact Us

📞WhatsApp: +86 137 3655 8515

📧 Solution Email: laserautomation@qq.com