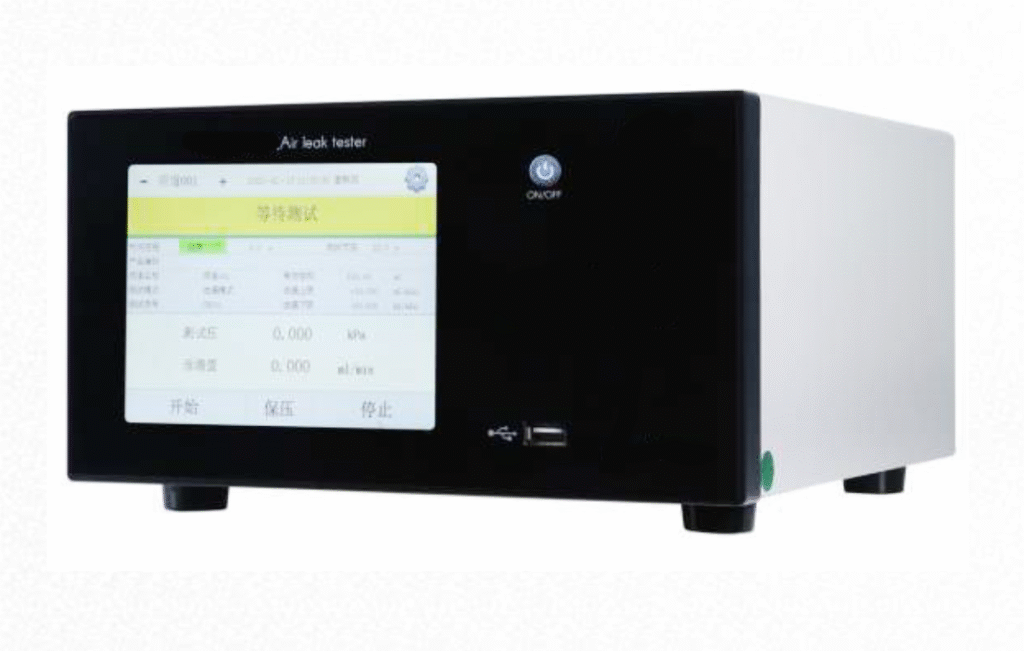

Assembly line airtightness leak detector

1. What is a Leak Tester for Air-Tightness?

A leak tester for air-tightness (often simply called a “leak tester”) is a precision instrument used to detect gas leaks in products or containers. It pressurizes (or evacuates) the test object and then monitors pressure or flow changes to determine—quantitatively or qualitatively—whether the seal meets required standards. It is a critical quality-control step in modern manufacturing for ensuring product safety, reliability, and performance.

2. How Does It Work? – Core Principle

All testers rely on one physical truth: “Any leak causes a pressure change.” A typical cycle has four stages:

- Charge – Compressed air (or a specific gas such as helium) is injected to a preset pressure.

- Stabilize – The pressure is held briefly to let temperatures and material stresses equalize.

- Test – A high-resolution sensor watches for pressure or flow changes.

- Pressure-decay method – Measures how much pressure drops in a fixed time; larger drop = larger leak.

- Differential-pressure method – Compares the part against a known “good” part; compensates for ambient temperature drift.

- Mass-flow method – Measures the exact amount of gas required to keep the pressure constant; higher flow = bigger leak.

- Helium-mass-spectrometry – Uses helium as a tracer and a mass spectrometer to detect minute leaks with ppm-level sensitivity.

- Exhaust – Gas is vented safely and the cycle ends.

3. Main Types – Technology & Characteristics

| Type | Principle | Key Features | Typical Uses |

|---|---|---|---|

| Positive-Pressure | Pressure-decay | Simple, low-cost; part must withstand internal pressure. | Outdoor LED lamps, water-purifier cartridges, any part with a fill port. |

| Vacuum (Negative-Pressure) | Vacuum-decay | Pulls vacuum inside; suitable for open or fragile parts. | Automotive accessories, small appliances, medical valve bodies. |

| Differential-Pressure | Compare vs. master | High accuracy, immune to temperature swings. | EV battery packs, motor housings, precision castings. |

| Helium-Mass-Spectrometry | Helium tracer + mass spec | Ultra-high sensitivity, leak can be located; high cost & complexity. | Aerospace parts, pacemakers, high-end electronics. |

| Mass-Flow (Quantitative) | Direct mass-flow reading | Measures actual leak rate, good for fully sealed products. | Smart watches, phones, electric toothbrushes. |

4. Where Is It Used? – Application Scenarios

- Automotive – Engine blocks, fuel systems, EV battery packs, wire-harness connectors (prevents oil, coolant, water intrusion).

- Consumer Electronics – Validates IP67/68 water- and dust-proofing for phones, earbuds, wearables.

- Medical Devices – Ensures sterile, leak-free infusion bags, syringes, pacemakers, breathing masks.

- Packaging – Checks food, pharma, and cosmetic packages for seal integrity to prevent spoilage or contamination.

- New Energy – Tests lithium-ion cells, battery modules, cooling plates for safety and performance.

5. How to Choose the Right Tester – Selection Guide

- Part Geometry & Port – Closed or open? Can it withstand positive pressure or only vacuum?

- Leak Rate Requirement – What is the maximum allowable leak in sccm or Pa·m³/s?

- Cycle Time – How many parts per minute/hour? Need multi-channel parallel testing?

- Accuracy vs. Budget – Differential-pressure often suffices; helium only for extreme sensitivity.

- Environment – Temperature compensation, vibration, humidity?

- Automation Integration – Robot loading, barcode traceability, SPC data export?

6. Advantages & Limitations

| Advantages | Limitations |

|---|---|

| Fast & accurate – Detects micro-leaks far better than visual checks. | Initial cost – High-precision units (especially helium) are expensive. |

| Non-destructive – Uses clean air or inert gases; no product damage. | Requires know-how – Fixture design and parameter tuning need training. |

| Automation-ready – Easy to integrate into production lines for 100 % inspection. | Environmental sensitivity – Pressure-decay can drift with temperature; compensation needed. |

Conclusion

A leak tester for air-tightness is the silent “gatekeeper” of modern industry. By applying scientific, quantitative methods, it guarantees that everything from the heart of a car to the circuitry in a phone, or even a life-saving medical device, remains safely sealed. Choosing the right tester is not just a technical decision—it is a direct investment in product quality, customer safety, and brand trust.