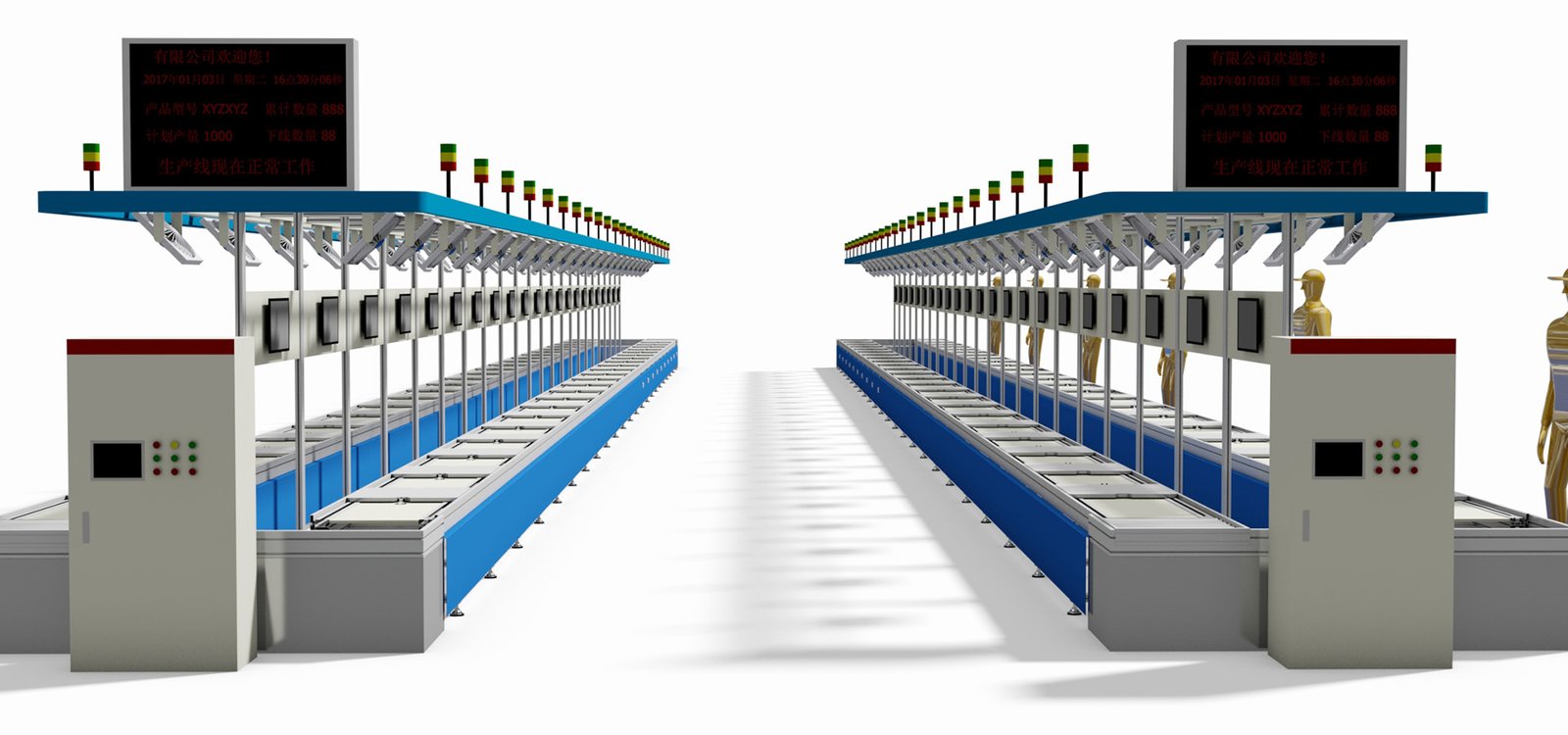

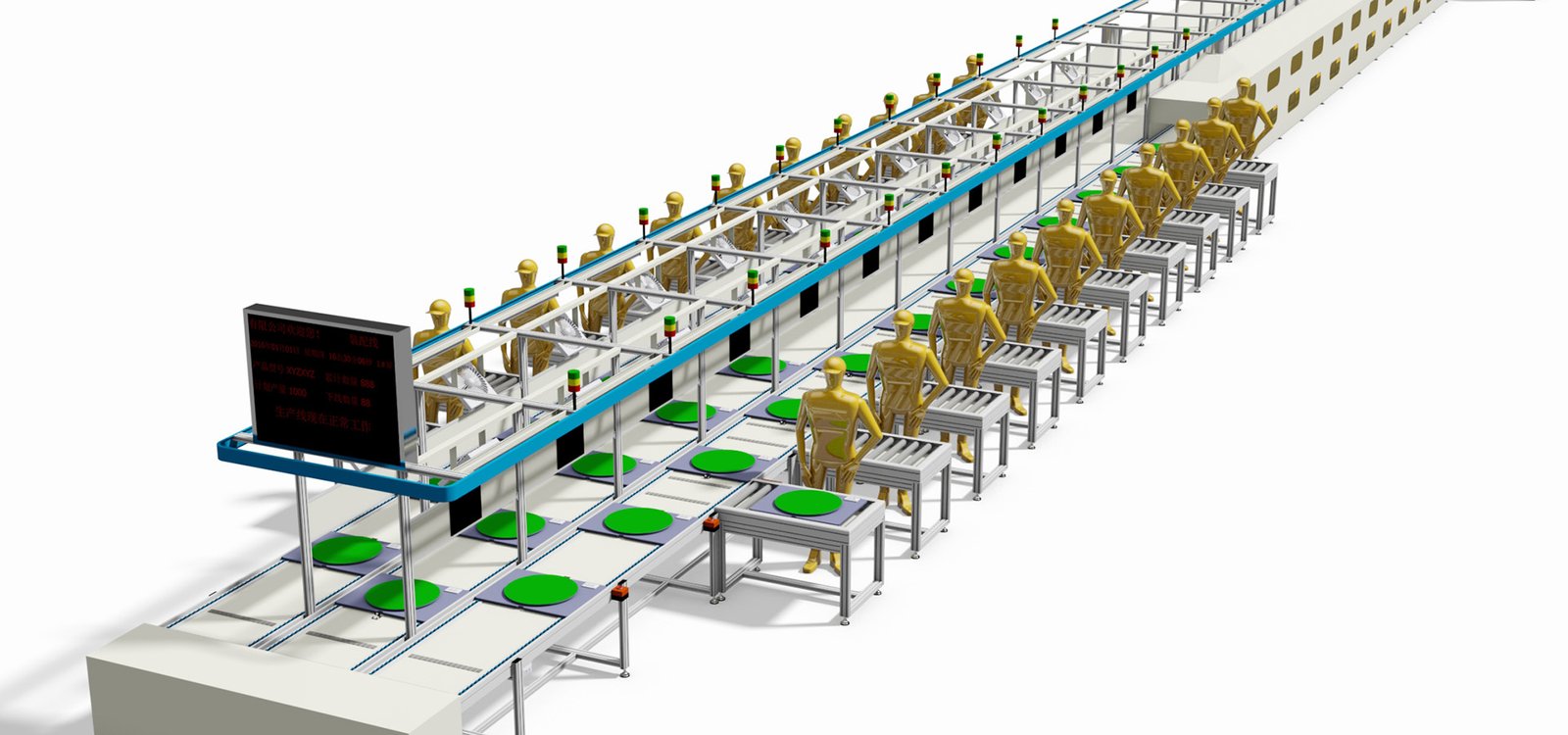

Assembly line chain conveyor plant

In assembly lines, chain conveyors are important components for material handling and product assembly. Here are some common types of chain conveyors:

- Flat Top Chain Conveyor: This conveyor has a flat surface suitable for placing various products, including those that require smooth movement, such as fragile or irregularly shaped items.

- Accelerated Chain Conveyor: Designed to increase production efficiency by speeding up the movement of materials.

- Plate Chain Conveyor: This type of conveyor uses a chain composed of flat plates, suitable for carrying heavy loads.

- Roller Chain Conveyor: This conveyor uses a chain with rollers to reduce friction and improve conveying efficiency.

- Modular Chain Conveyor: Highly flexible and customizable, this conveyor can be easily adjusted in length and direction to meet specific needs.

- Slat Chain Conveyor: This conveyor uses a chain with slots, capable of carrying various shapes and sizes of items.

- Overhead Chain Conveyor: Suspended from the ceiling or supports, this conveyor is suitable for environments with limited space.

- Mesh Belt Chain Conveyor: This conveyor uses a mesh belt, suitable for conveying products that require ventilation or to prevent items from rolling.

- Spiral Chain Conveyor: Designed for vertical or inclined material transport, often used to elevate materials to different floors or work areas.

- Telescopic Chain Conveyor: This conveyor can be extended or retracted as needed, suitable for situations where the conveying distance needs to be flexibly adjusted.

Each type of chain conveyor has its specific applications and advantages, and choosing the right type is crucial for improving the efficiency and effectiveness of the assembly line.

The benefits of conveyor systems in assembly production are manifold, and here are some of the main advantages:

- Improved Efficiency: Conveyors can continuously move products, reducing the time and labor intensity of manual handling, thereby increasing overall production efficiency.

- Reduced Errors: Automated conveyor systems reduce human errors because they operate according to preset programs, minimizing operational mistakes.

- Space Saving: Conveyor systems can be designed in straight lines, curves, or multi-level configurations, effectively utilizing space, especially when floor space is limited.

- Flexibility: Many conveyor systems can be easily adjusted to accommodate different product sizes, shapes, and production requirements.

- Improved Working Conditions: By reducing the handling of heavy objects, conveyors help reduce workplace injuries and accidents.

- Ease of Integration: Conveyors can be easily integrated with other automated equipment (such as robots, automated inspection systems) to form a complete automated production line.

- Enhanced Product Quality: By reducing human intervention, conveyors help maintain product consistency and quality.

- Reduced Work in Process (WIP): Conveyors can reduce the inventory of work in process during production because products can move through the production line more quickly.

- Cost-Effective: Although the initial investment may be high, automated conveyor systems can reduce labor costs and increase production efficiency in the long run, thus improving the return on investment.

- Easy Maintenance: Modern conveyor designs usually consider the convenience of maintenance, making regular inspections and maintenance easier.

- Scalability: As production demands grow, many conveyor systems can be scaled up to accommodate increased output.

- Environmentally Friendly: Automated conveyors reduce reliance on manual labor, helping to reduce energy consumption and waste production.

These benefits make conveyor systems an indispensable part of modern manufacturing, especially in production environments that pursue high efficiency and high output.

Selecting the right conveyor system for your production line is crucial for efficiency and productivity. Here are some key factors and steps to help you choose the appropriate conveyor system for your production line:

- Determine Needs:

- Assess your production requirements, including product types, sizes, weights, and production volumes.

- Determine the speed and pace of the production line.

- Space Planning:

- Consider available space and layout constraints.

- Determine the optimal path and configuration for the conveyor system.

- Product Characteristics:

- Consider the physical characteristics of the products, such as shape, size, weight, and fragility.

- Determine if special handling is required, such as anti-static, dust-free, or temperature and humidity control.

- System Type:

- Choose the appropriate type of conveyor system based on product characteristics and production needs, such as belt conveyors, chain conveyors, or roller conveyors.

- Level of Automation:

- Assess automation needs, including the integration of sensors, robots, or other automated equipment.

- Consider future expandability and upgrade possibilities.

- Cost-Benefit Analysis:

- Evaluate the initial investment and operational costs of different conveyor systems.

- Consider long-term benefits, including improved production efficiency and reduced labor costs.

- Supplier Evaluation:

- Research and compare the products and services of different suppliers.

- Consider the supplier’s reputation, technical support, and after-sales service.

- Safety Considerations:

- Ensure that the chosen system meets safety standards and regulatory requirements.

- Consider the safety and health of operating personnel.

- Maintenance and Support:

- Consider the maintenance requirements and costs of the system.

- Ensure that the supplier provides necessary technical support and spare parts supply.

- Testing and Validation:

- Test the performance of the conveyor system in a real environment to ensure it meets production needs.

- Validate the reliability and stability of the system.

- Environmental Impact:

- Consider the energy efficiency and environmental impact of the system.

- Choose environmentally friendly materials and energy-saving designs.

- Flexibility and Scalability:

- Consider potential future production changes and ensure that the system has sufficient flexibility and scalability.

By considering these factors, you can choose the most suitable conveyor system for your production line to improve production efficiency, reduce costs, and ensure product quality.