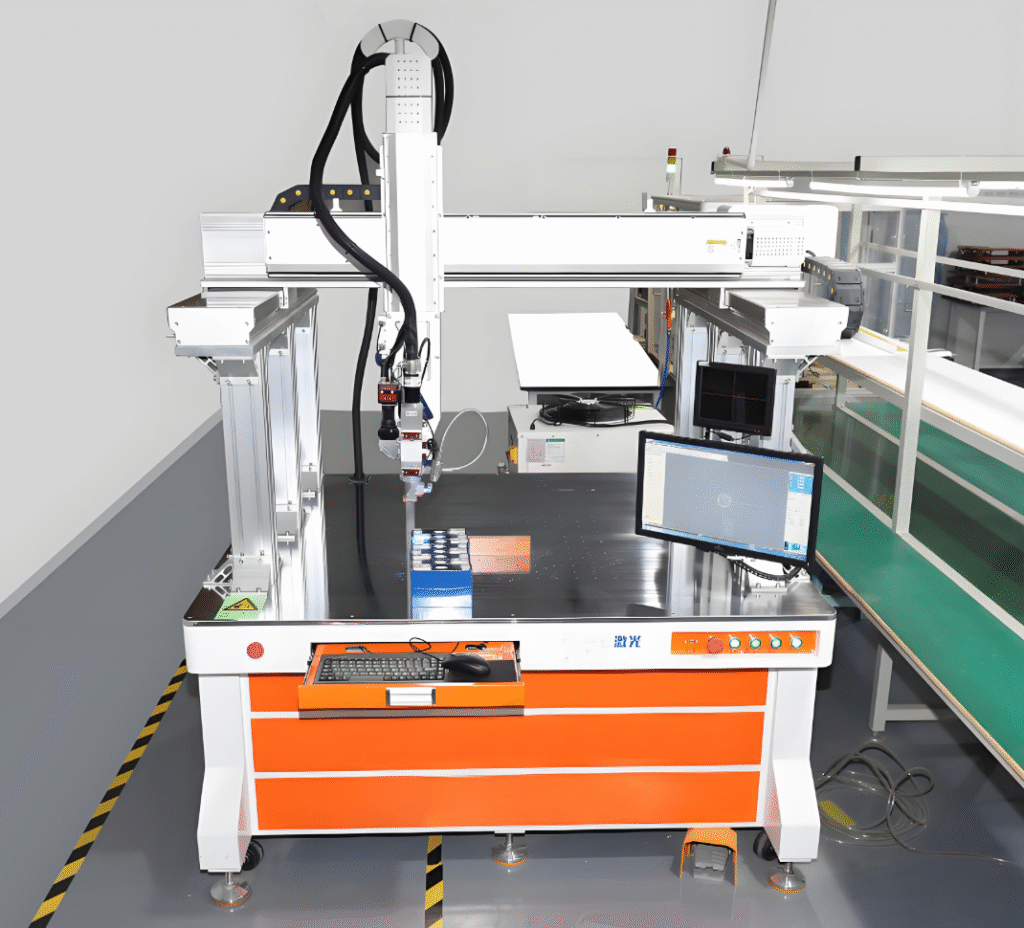

Laser welding equipment for lithium battery assembly lines

Laser Welding Equipment for Lithium Battery Assembly Lines

Generic Technical Description & Selection Table

- Purpose of the Equipment

Laser welding runs through the three main levels—cell → module → PACK—and joins copper or aluminum components such as tabs, busbars, and caps into highly reliable, low-resistance electrical paths while ensuring hermetic sealing. - Process Stations & Corresponding Welding Tasks

| Process Step | Welded Joint | Welding Goal | Typical Laser Solution |

|---|---|---|---|

| Cell Pre-treatment | Tab cutting / shaping | Remove burrs, fix dimensions | Precision laser cutting |

| Cell Assembly | Tab-to-busbars | Series/parallel electrical connection | Fiber laser 2–6 kW |

| Cell Sealing | Cap-to-can | Seal against leakage | Continuous fiber 3–6 kW |

| Module Assembly | Busbar-to-pole | Module-level connection | Gantry or robot |

| PACK Integration | Inter-module links | Pack-level connection | High-power laser |

- Key Technical Specifications

| Parameter | Typical Range | Selection Hint |

|---|---|---|

| Laser Power | 200 W – 6 kW | Tabs/foils 200–500 W; cap/thick plates ≥3 kW |

| Laser Type | QCW or CW fiber | Must handle high-reflectivity Cu & Al |

| Welding Speed | 10 – 300 mm/s | High-throughput lines prefer galvo + high power |

| Position Accuracy | ±10 – ±100 µm | Highest for tab station |

| Work Envelope | 50 × 50 mm – 2 000 × 1 000 mm | Depends on cell size + fixture |

| Cooling | Air / Water | ≥1 kW recommend water cooling |

| In-Process Monitoring | Power feedback, seam tracking, IR pyrometry | Guarantees traceability |

| Safety & Environmental | Enclosure + fume extraction | Meets Class 1 laser safety |

- Generic Selection Table (Brand-Neutral)

| Station | Laser Power | Laser Mode | Welding Speed | Position Accuracy | Typical Configuration | Typical Materials / Thickness |

|---|---|---|---|---|---|---|

| Precision Tab Weld | 200–500 W | QCW | 10–50 mm/s | ±10 µm | Galvo + coaxial vision | Cu/Al 0.1–0.4 mm |

| Cap Sealing Weld | 3–4 kW | CW | 200–300 mm/s | ±25 µm | Gantry + wobble head | Al 0.8–2 mm |

| Module Busbar Weld | 2–6 kW | CW | 80–150 mm/s | ±50 µm | Robot + fume extraction | Cu 1–3 mm / Al 1–3 mm |

| PACK Main Weld | 4–6 kW | CW | 50–120 mm/s | ±100 µm | Gantry / Robot | Al 2–5 mm |

- Generic Selection Workflow

- Define cell type (cylindrical / prismatic / pouch) and dimensions.

- List material types + thicknesses + layer counts → calculate required laser power.

- From target throughput → determine welding speed and number of parallel stations.

- Evaluate line takt → choose galvo, gantry, or robot structure.

- Verify fixture compatibility → confirm work envelope and change-over time.

- Assess safety & environmental needs → add guarding and fume extraction.

Follow the steps above to match equipment without any brand preference.