Quick-Connect Couplings for In-ProductionLine Air-Tightness Testing

Quick-Connect Couplings for In-Line Air-Tightness Testing

(also called quick-seal or quick-change fittings)

- Purpose

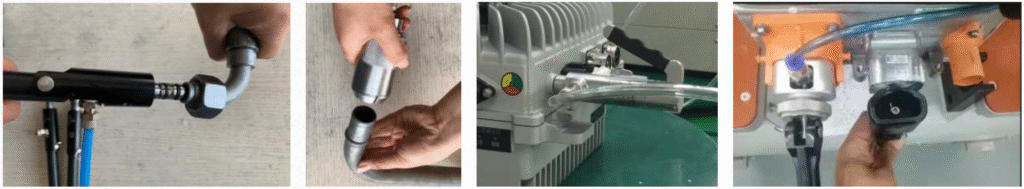

In 1–2 seconds, they create a leak-tight seal between the test item (engine housing, battery pack, plastic tube, etc.) and the leak-tester circuit, then release instantly after the test—keeping takt time short, leaks zero, and parts unscratched. - Typical Designs

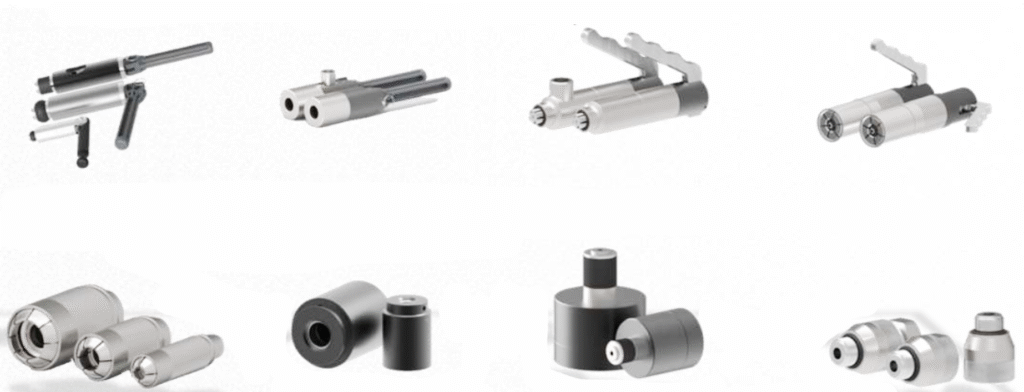

a) Radial-expansion type

• Elastic seal ring expands against the inner wall of a smooth bore.

• Fits bore diameters with H7–H11 tolerance.

b) Face-seal (end-load) type

• Flat seal ring is pressed against the part’s end-face by an outer cone.

• Ideal for flanged ports or tube ends.

c) Quick-thread type

• Floating nut locks with a ¼-turn after insertion; self-compensates for thread pitch errors.

• Used on standard internal threads.

d) Push-to-connect sleeve type

• Slide sleeve forward → insert tube → release sleeve to lock; push sleeve again to release.

• Works on 4–20 mm OD rigid or flexible tubing.

e) Pneumatic clamp type (robot EOAT)

• Driven by cylinder or servo; adjustable compression and position sensor feedback.

• Suited for fully automated, mixed-model lines.

| Item | Summary |

|---|---|

| Purpose | Seal-test-release in 1–2 s; keeps takt time, zero leakage, zero scratches |

| Typical Designs | ① Radial-expansion ② Face-seal ③ Quick-thread ④ Push-to-connect sleeve ⑤ Pneumatic clamp |

| Key Specs | ≤ 1×10⁻⁴ mbar·L/s leak rate; 0–1 MPa proof pressure; ≥ 1 million cycles; –20 °C to 120 °C |

| Selection Guide | Interface type/size → test pressure → cycle time → environment |

| Installation & Care | Floating mount ±0.5 mm; daily grease; inspect seals monthly or every 10 k cycles; 40 µm upstream filter |

| One-liner | Pick the right quick coupling—seal in a second, release in a second—so the leak station never slows the line. |

- Key Specifications

- Leak rate: ≤ 1 × 10⁻⁴ mbar·L/s (helium)

- Operating pressure: 0–1 MPa (high-pressure versions to 3 MPa)

- Insertion cycles: ≥ 1 million

- Temperature range: –20 °C to +120 °C (with FKM or silicone seals)

- Repeatability: ±0.1 mm (robotic versions)

- Four-Step Selection

- Interface: bore, tube OD, or thread—what size and tolerance?

- Pressure: test pressure plus any surge.

- Takt: manual ≤ 3 s, automated ≤ 1 s; need venting on release?

- Environment: dust, oil mist, high heat? Choose 316 stainless + FKM seals.

- Installation & Maintenance

- Mount on a floating bracket to absorb ±0.3–0.5 mm part-position error.

- Lightly grease seals daily with silicone-based lubricant.

- Inspect seals every 10 000 cycles or monthly; keep 5 % spares in stock.

- Install a 40 µm upstream filter to prevent chips from damaging seal faces.

One-sentence takeaway

“For in-line leak testing, the right quick coupling seals in one second and releases in one second—match the interface, pressure and durability, and the leak station will never slow the line.”