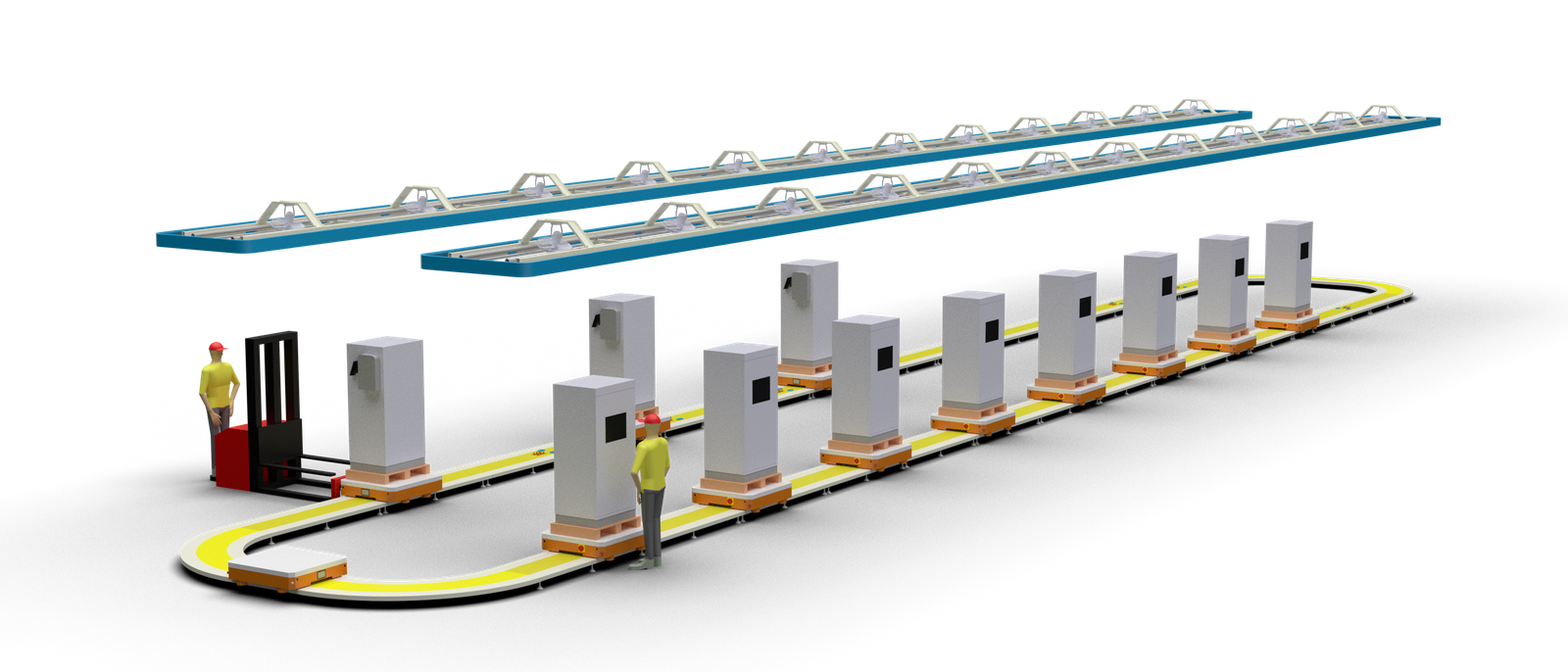

RGV (Rail Guided Vehicle) for assembly lines

Here is the detailed itemized description of RGV (Rail Guided Vehicle) used in assembly lines:

I. Structural Features

- Vehicle Body Structure

- Composed mainly of the frame, drive wheels, driven wheels, front and rear bumpers, electrical system, and protective cover plates.

- The frame is typically made of high-strength steel, offering excellent load-bearing capacity and resistance to deformation.

- Drive System

- Usually employs a combination of servo motors and reducers, supporting bidirectional movement and synchronized control.

- High-end models feature leaf spring suspension structures to ensure the drive wheels remain pressed against the rail, preventing slippage and positioning errors.

- Power Supply

- Commonly uses conductor rail power supply (e.g., brands like VAHLE, Panasonic); some models use battery power.

- Communication and Positioning System

- Communication methods include optical communication, Wi-Fi, RFID, etc.

- Positioning methods include laser ranging, RFID + photoelectric switches, encoder feedback, with positioning accuracy reaching ±2mm to ±5mm.

- Safety Protection System

- Equipped with safety edge switches, laser ranging, optical communication obstruction detection, etc., supporting emergency braking.

II. Control Methods

- Control Modes

- Supports manual, single-machine automatic, and networked automatic modes, allowing flexible switching.

- Scheduling System

- Usually centrally controlled by a host computer, supporting integration with MES systems for task allocation and path optimization.

- Path Control

- Fixed-path operation; rails can be straight, circular, or branched, suitable for multi-station handling.

- Remote Control and Monitoring

- Supports remote control operation, with real-time monitoring, status feedback, and abnormal alarm functions.

III. Advantages

- High Efficiency

- Fast operating speed (up to 160–200 m/min), suitable for high-frequency handling tasks.

- High Reliability

- Fixed rail ensures stable operation, low failure rate, and easy maintenance.

- Precise Positioning

- Combines multiple positioning methods for high repeatability, suitable for high-precision assembly.

- Cost-Effective

- Simple structure, mainly uses standard domestic components, with lower manufacturing and maintenance costs compared to AGVs.

- High Safety

- Reduces manual handling, lowers operational risks; equipped with multiple safety protection mechanisms.

- Strong Adaptability

- Capable of operating in harsh environments (e.g., high temperature, dust), and supports heavy loads (up to 5 tons).

IV. Application Scenarios

- Assembly Lines

- Used in automotive, injection molding, aerospace, and other industries for precise material transport between workstations.

- Automated Warehouses

- Works with automated storage systems to realize automatic material handling, storage, and sorting.

- Production Line Logistics

- Connects with conveyors, lifts, robots, etc., to build automated logistics systems.

- Multi-Variety, Small-Batch Production

- Supports mixed-model production and customized order processing, meeting flexible manufacturing needs.

- Special Environment Applications

- Suitable for cold-rolled steel pipe workshops, chemical plants, aerospace, and other scenarios requiring high handling precision and stability.