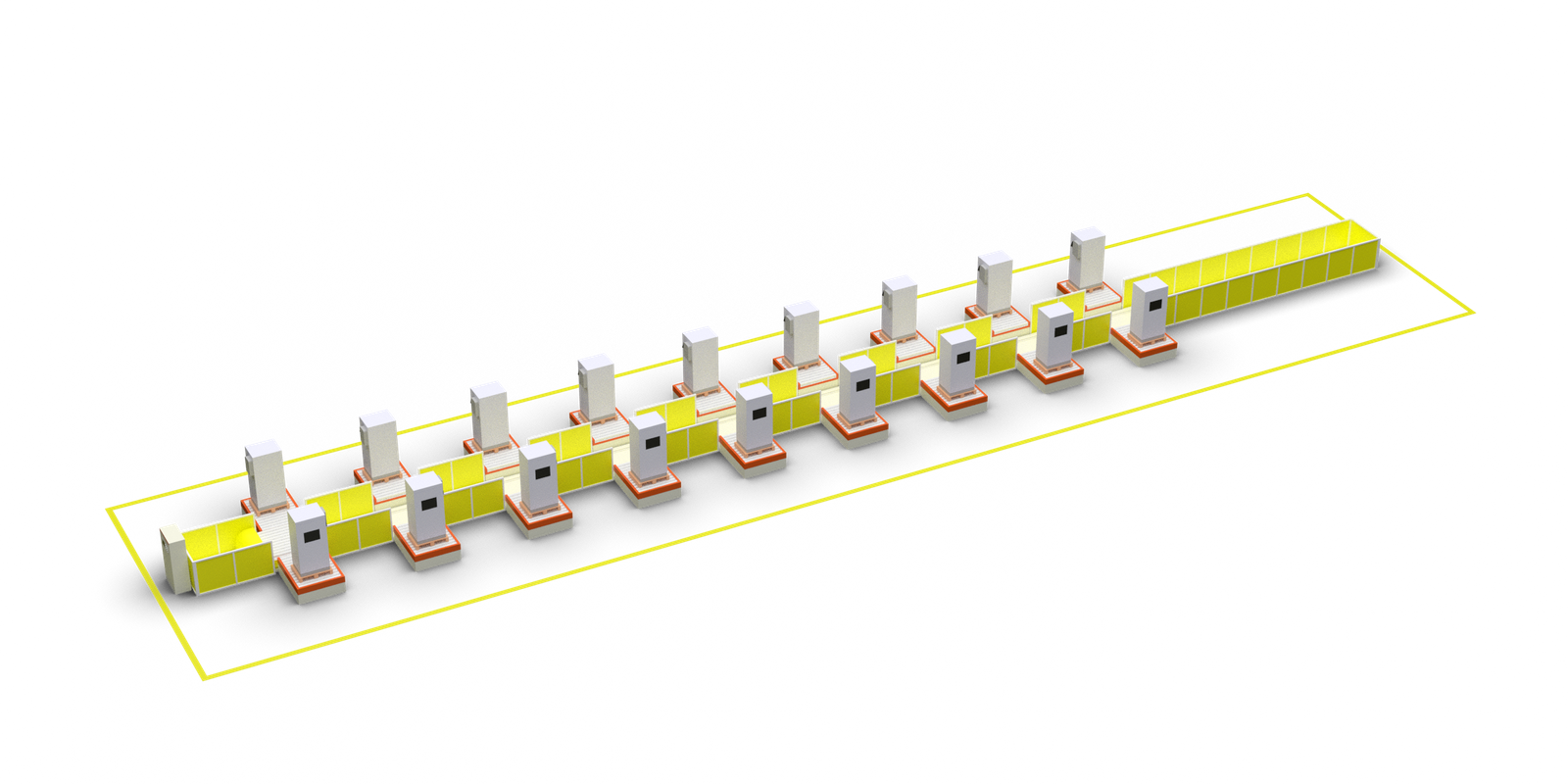

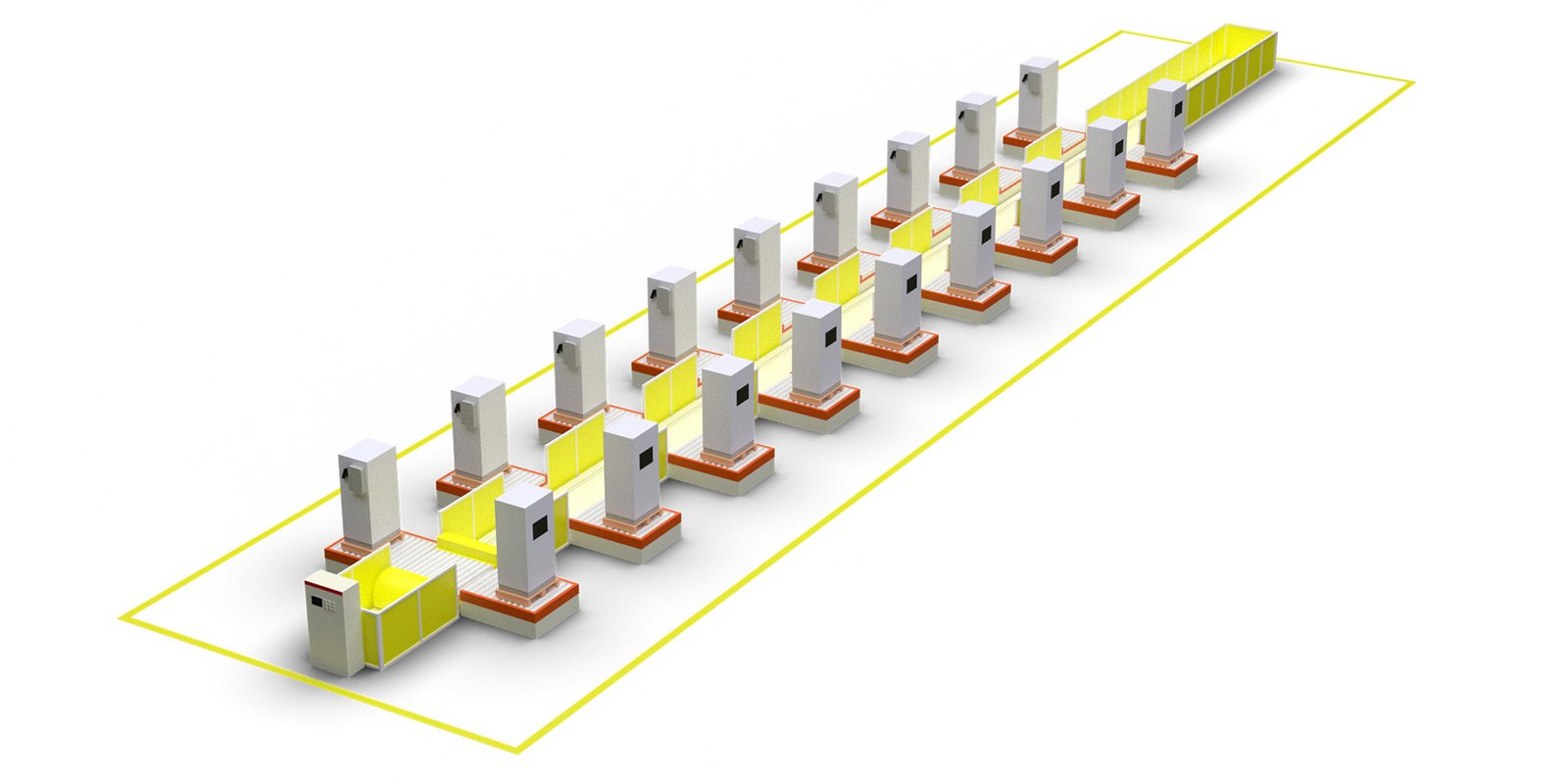

RGV-type conveyor line for small-batch product assembly

This RGV-based assembly line uses a single center-mounted conveyor-equipped shuttle to carry standardized pallets between compact side transfer stations. Modular aluminum stations can be quickly swapped or extended, while RFID routing lets mixed small-batch products follow configurable paths. The RGV travels on a low-profile rail, docks within ±0.5 mm, and exchanges pallets in seconds; safety scanners and edges protect operators. The layout needs only one-third the floor space of a slat-chain line, supports 30-180 s takt, and is ready for MES and robot docking.

✅ 1. System Structure & Layout Logic

1.1 System Components

- RGV (Rail Guided Vehicle): One unit, equipped with行走 (travel), 定位 (positioning), and 托盘输送 (pallet conveying) functions.

- Side Transfer Stations: Symmetrically arranged on both sides for manual operations or automatic docking.

- Pallet System: Standardized pallets compatible with various product fixtures.

- Control System: PLC + sensors + RFID, supporting flexible process routing.

- Safety System: Laser scanner + safety edges + emergency stops, meeting PLd safety level.

1.2 Layout Logic

- The RGV travels along a central rail, transferring pallets between stations.

- Each side has multiple independent transfer stations, forming workstations.

- Operators or equipment work on pallets at the stations; RGV handles scheduling.

- Supports flexible routing: skipping stations, returning pallets, parallel paths, etc.

✅ 2. RGV Design (Center Conveyor Type)

2.1 Travel Mechanism

- Drive: Dual-wheel differential drive, servo motor + gearbox, adjustable speed (0.1–0.5 m/s).

- Guidance: Single rail + side guide rollers for smooth travel.

- Positioning: Barcode/QR code + servo control, repeatability ±0.5 mm.

- Power Supply: Conductor rail or battery-powered (optional), supports continuous operation.

2.2 Onboard Conveyor

- Type: Dual-chain / timing belt / motorized rollers, selected based on pallet weight/size.

- Width: Matches standard pallets (e.g., 400 mm).

- Speed: 0.1–0.3 m/s, synchronized with transfer stations.

- Positioning: Lift-pin mechanism to lock pallet on RGV.

2.3 Control & Communication

- Controller: Onboard PLC or remote I/O, wireless Ethernet to main controller.

- Sensors:

- Pallet presence (photoelectric)

- Pin status (magnetic)

- Safety edge & laser scanner status

- ID System: RFID reader for pallet info, supports multi-product mixed flow.

✅ 3. Transfer Station Design (Side-Mounted)

3.1 Structure

- Frame: Industrial aluminum profile + sheet metal base, modular assembly.

- Top Type:

- Non-powered rollers (light load, manual push)

- Motorized rollers (medium load, automatic)

- Lift & transfer unit (heavy load or redirection needed)

- Height: Aligned with RGV (typically 750 mm) for smooth handoff.

3.2 Positioning & Docking

- Pin Hole: Matches RGV lift pin for accurate docking.

- Stopper: Pneumatic or spring stopper to prevent pallet drift.

- Sensors:

- Pallet-in-place detection

- Operation-complete button or barcode scan

- Optional safety light curtain

3.3 Quick Changeover Support

- Tabletop with standard hole grid (e.g., 50×50 mm) for fast fixture adjustment.

- Whole station can be swapped in <5 minutes.

- Fixture sub-plate detachable from pallet; only sub-plate needs changing for new product.

✅ 4. Pallet & Fixture System

4.1 Pallet Structure

- Size: Standardized, e.g., 400×600 mm, 12 mm thick.

- Material: Aluminum alloy or engineered plastic, lightweight and strong.

- Interfaces:

- Corner bushings for RGV/station pins

- RFID tag slot underneath

- Mounting hole grid (M6 threaded or dowel holes)

4.2 Fixture Design

- Sub-plate: 300×400 mm replaceable fixture plate, hand-screw mounted.

- Clamping: Manual quick clamps, pneumatic grippers, magnets, etc.

- Compatibility: Multi-product pallets; only sub-plate changed for new product.

✅ 5. Control & Information System

5.1 Control Architecture

| Level | Devices | Function |

|---|---|---|

| Device | RFID, servo, I/O | Real-time sensing & actuation |

| Control | PLC + HMI | Routing, RGV control, station management |

| Info | MES interface (optional) | Work order, routing, traceability |

5.2 Process Flow Example (Single-Piece Flow)

- Operator loads pallet at load station → presses “Call”.

- RGV arrives → pallet transfers onto RGV → lift pins lock.

- RGV moves to next station per routing table.

- After operation, operator presses “Release”.

- RGV returns, picks up pallet → continues.

- At last station, RGV sends pallet to unload station.

- Empty pallet can be returned manually or via optional return line.

5.3 Multi-Product Mixed Flow

- Each pallet RFID contains: product type, routing, quality status.

- RGV reads info and auto-selects path.

- Supports skipping, rework, parallel paths.

- Changeover: swap fixture sub-plate and select new product on HMI.

✅ 6. Safety & Ergonomics

6.1 Safety Systems

- Laser Scanner: 270° detection, zoned减速/停止 (slowdown/stop).

- Safety Edges: On RGV, trigger immediate stop.

- E-Stops: On RGV and key stations.

- Safety PLC: Handles all safety signals, PLd level.

- Audible/Visual Alarms: Indicate RGV status/faults.

6.2 Ergonomics

- Table height 750 mm, suitable for Asian operators.

- Buttons/scanner within arm’s reach, no twisting.

- Pallet flow direction consistent, minimal turning.

- Optional LED lighting and fan on station frame.

✅ 7. Expansion & Upgrade Options

| Direction | Description |

|---|---|

| Add Stations | Rail extendable; RGV program auto-scales routing |

| Auto Load/Unload | Dock SCARA or 6-axis robot to station |

| Pallet Return Line | Add empty-pallet return conveyor, closed loop |

| MES Integration | Real-time upload of operation & quality data |

| Dual RGV | Add second RGV for higher throughput (<60 s takt) |

✅ 8. Summary: Key Advantages

| Feature | Benefit |

|---|---|

| High Flexibility | Multi-product mixed flow, configurable routing, fast changeover |

| Space-Saving | Line length ~1/3 of traditional slat chain, fits small workshops |

| Easy Expansion | Modular stations, scalable control & rail |

| Controllable Investment | Single RGV + modular stations, pay-as-you-grow |

| Digital-Ready | RFID + MES interface, future-proof for Industry 4.0 |