I. Basic Parameters

1. Power Range

- Range: 1500W – 30000W

- Description: The power of a laser cutting machine directly affects its cutting capability and efficiency. A 1500W laser is suitable for thin sheet processing, while a 30000W laser can cut thicker metal sheets and even some high-strength materials.

2. Processing Platform Size

- Range: 1300×1300 mm to 12000×2500 mm

- Description: The size of the processing platform determines the maximum size of the workpiece that the machine can handle. Smaller platforms are suitable for processing small parts, while larger platforms are designed for large-scale production or large workpieces.

3. Positioning Accuracy

- Range: ±0.03 mm to ±0.05 mm

- Description: Positioning accuracy refers to the minimum positional deviation that the machine can achieve during movement. High positioning accuracy ensures the precision of the cutting path and reduces processing errors.

4. Repeatability

- Range: ±0.02 mm to ±0.03 mm

- Description: Repeatability is the accuracy with which the machine can return to the same position multiple times. High repeatability is crucial for batch production, ensuring consistency across each workpiece.

5. Maximum Acceleration

- Range: 0.6G to 1.5G

- Description: Maximum acceleration determines the dynamic performance of the machine during rapid movement. Higher acceleration can reduce processing time and improve production efficiency.

6. Maximum Travel Speed

- Range: 45 m/min to 120 m/min

- Description: Maximum travel speed refers to the highest speed at which the cutting head can move when not cutting. Higher travel speeds can reduce non-cutting time and improve overall processing efficiency.

7. Cutting Head Type

- Type: Auto-focus cutting head

- Description: An auto-focus cutting head can automatically adjust the focal position according to changes in the workpiece surface, ensuring stable cutting quality. This is particularly important for workpieces of different thicknesses and shapes.

8. Cooling System

- Type: Water-cooling system

- Description: A water-cooling system is used to cool the laser generator and optical components, preventing overheating. This is especially important for high-power lasers to ensure stable machine operation.

9. CNC System

- Functions: High-performance CNC system with features such as automatic edge finding, automatic nesting, and auto-focus

- Description: The CNC system is the core of the laser cutting machine, controlling the movement of the machine and the output of the laser. Advanced CNC systems can plan complex cutting paths and automate operations, improving production efficiency and cutting quality.

10. Laser Generator Type

- Type: Fiber laser or CO₂ laser

- Description: Fiber lasers are known for their high efficiency and beam quality, making them suitable for metal processing. CO₂ lasers, on the other hand, perform well when cutting non-metal materials. The choice depends on the material and process requirements.

11. External Optical Path Protection

- Configuration: Equipped with protective covers and positive-pressure protective gas

- Description: Protective covers and positive-pressure protective gas can prevent contamination of optical components, extending the life of the equipment and ensuring stable cutting quality.

12. Maximum Cutting Gas Pressure

- Pressure: 1.6 MPa (for some machines)

- Description: Cutting gas pressure affects cutting quality and speed. Higher gas pressure can improve cutting quality and speed, but it needs to be adjusted according to the material and thickness.

13. Cutting Materials

- Material Types: Stainless steel, carbon steel, alloy steel, galvanized sheet, copper sheet, aluminum sheet, and other metal sheets

- Description: Different materials have different processing characteristics. The laser cutting machine needs to adjust cutting parameters according to the reflectivity, melting point, and thermal conductivity of the material to achieve the best cutting results.

14. Cutting Thickness Range

- Range: Varies from thin sheets to thick plates depending on power and material type

- Description: The cutting thickness capability of a laser cutting machine depends on the laser power and material characteristics. High-power lasers can cut thicker metal sheets, but cutting parameters need to be optimized to ensure cutting quality.

15. Control System Functions

- Functions: Supports basic processes such as flying cutting, frog jumping, compensation, lead-in lines, micro-links, pre-piercing, and cutting with film

- Description: These functions can improve cutting efficiency and quality, reduce processing time, and are suitable for complex cutting tasks and processing scenarios with high precision requirements.

II. Structural Composition

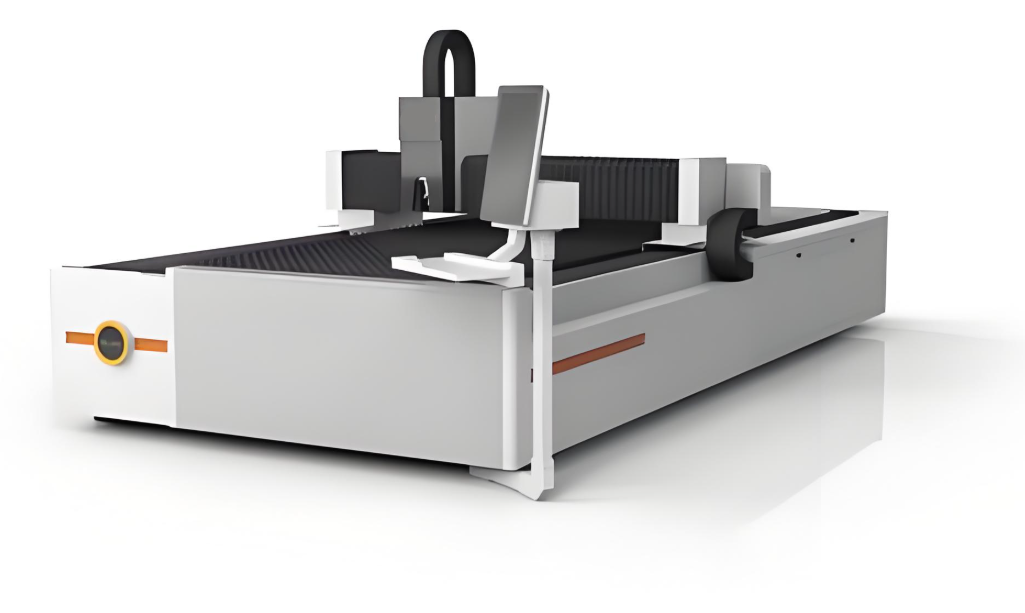

1. Machine Tool Host

- Function: Achieves movement along the X, Y, and Z axes, including the cutting work platform for placing workpieces to be cut.

- Features: Typically driven by servo motors to ensure precise and stable movement. A high-rigidity bed design can reduce vibration and improve cutting quality.

2. Laser Generator

- Function: Produces the laser beam.

- Features: For laser cutting, fiber lasers or CO₂ gas lasers with high electro-optical conversion efficiency and the ability to output higher power are usually used. The performance of the laser generator directly affects cutting quality and efficiency.

3. External Optical Path

- Function: Directs the laser to the desired direction.

- Features: Includes reflective mirrors, all of which are protected by covers and supplied with clean positive-pressure protective gas to prevent contamination of the mirrors. The design of the external optical path needs to ensure the transmission efficiency and stability of the laser.

4. CNC System

- Function: Controls the machine’s movement along the X, Y, and Z axes and also controls the output power of the laser generator.

- Features: High-performance CNC systems can plan complex cutting paths and automate operations, improving production efficiency and cutting quality. Advanced CNC systems also support various intelligent functions such as automatic edge finding and automatic nesting.

5. Cooling System

- Function: Cools the laser generator and optical components.

- Features: Mainly a water chiller, used to prevent the equipment from overheating. The cooling system design needs to ensure the circulation efficiency and temperature control of the coolant to ensure stable machine operation.

6. Focusing and Tracking System

- Function: Automatically adjusts the focal position according to changes in the workpiece surface.

- Features: Composed of a focusing cutting head and a tracking sensor system, ensuring stable cutting quality. The auto-focus function can adapt to workpieces of different thicknesses and shapes, improving cutting efficiency.

III. Application Scope

1. Material Types

- Applicable Materials: Stainless steel, carbon steel, alloy steel, spring steel, galvanized sheet, copper sheet, aluminum sheet, and other metal sheets.

- Description: Laser cutting machines can adjust cutting parameters according to the characteristics of different materials to achieve efficient and precise processing.

2. Industry Applications

- Application Fields:

- Sheet Metal Processing: For manufacturing various sheet metal parts.

- Advertising Signage and Letter Making: Cutting metal signs and letter molds.

- High and Low Voltage Electrical Cabinet Manufacturing: Processing metal casings for electrical cabinets.

- Mechanical Parts: Manufacturing various mechanical parts and components.

- Kitchenware: Cutting stainless steel kitchenware parts.

- Automotive: Processing automotive parts.

- Metal Crafts: Making metal crafts and decorations.

- Saw Blades: Cutting saw blades and other tools.

- Electrical Components: Processing electrical parts.

- Optical Industry: Cutting parts for eyeglass frames and other components.

- Spring Sheets: Manufacturing spring sheets and other elastic components.

- Circuit Boards: Cutting the metal parts of circuit boards.

- Medical Microelectronics: Processing medical devices and microelectronic components.

- Hardware: Manufacturing various hardware tools and components.

- Cutting Tools and Gauges: Cutting metal parts for cutting tools and gauges.

3. Processing Techniques

- Supported Techniques:

- Flying Cutting: The cutting head cuts while moving, improving efficiency.

- Frog Jumping: The cutting head quickly moves to the next cutting point, reducing non-cutting time.

- Compensation: Automatically compensates for the cutting path to ensure cutting accuracy.

- Lead-in Lines: Adding lead-in lines at the cutting start point to avoid defects at the start.

- Micro-links: Adding micro-links between cutting paths to prevent workpiece displacement.

- Pre-piercing: Pre-piercing at the cutting start point to ensure the accuracy of the cutting start.

- Cutting with Film: Cutting while keeping the protective film on the material surface to prevent contamination.

These detailed descriptions comprehensively showcase the performance characteristics, structural composition, and application scope of single-platform CNC laser cutting machines, helping users better understand and select the equipment that suits their production needs.