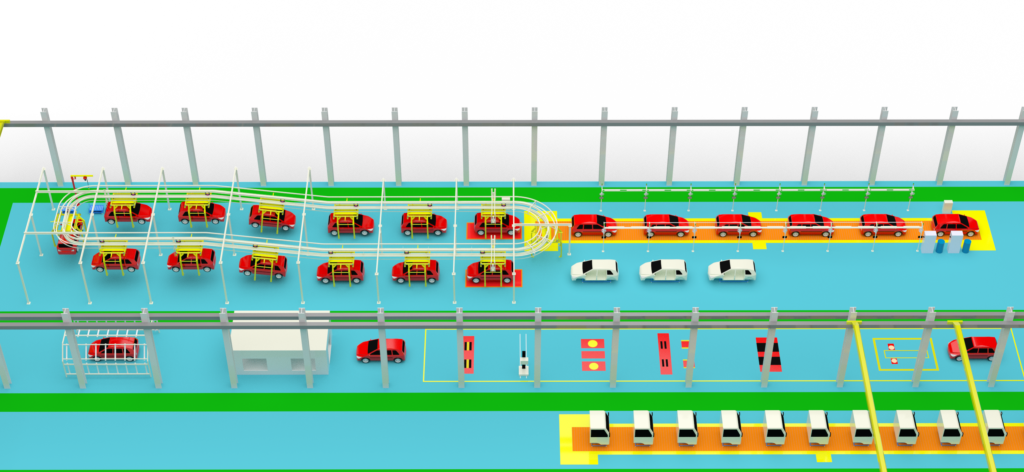

The assembly lines for monocoque sedans and body-on-frame pickups have distinct features. Monocoque sedans use overhead conveyor chains and floor plate conveyors, starting with initial interior assembly, followed by chassis assembly, secondary interior work, and final inspection/testing. In contrast, body-on-frame pickups employ follower frames or chain traction trolleys. They begin with chassis pre-assembly, then install the body, add interior/exterior components, and undergo final checks. Both lines ensure vehicle quality through rigorous testing before storage.

Assembly Lines for Monocoque Sedans and Body-on-Frame Pickups

Monocoque Sedan Assembly Line

The assembly line for monocoque sedans mainly adopts the form of conventional overhead conveyor chains combined with floor-based plate conveyors. The workflow is as follows:

Process Flow Chart

| Process Stage | Monocoque Sedan | Body-on-Frame Pickup |

|---|---|---|

| Body Storage and Interior Assembly | The body is hung on the overhead conveyor chain and the first stage of interior assembly is completed | Chassis pre-assembly, body installation on the chassis |

| Chassis Assembly | Installation of engine, transmission, suspension system, etc. | Installation of front and rear axles, engine, transmission, etc. |

| Secondary Interior Assembly | Installation of doors, windows, etc. | Installation of interior components such as seats and dashboards |

| Final Inspection and Testing | Wheel alignment, rain testing, road testing, etc. | Wheel alignment, rain testing, road testing, etc. |

| Final Assembly and Storage | Window tinting, floor mat installation, etc. | Window tinting, floor mat installation, etc. |

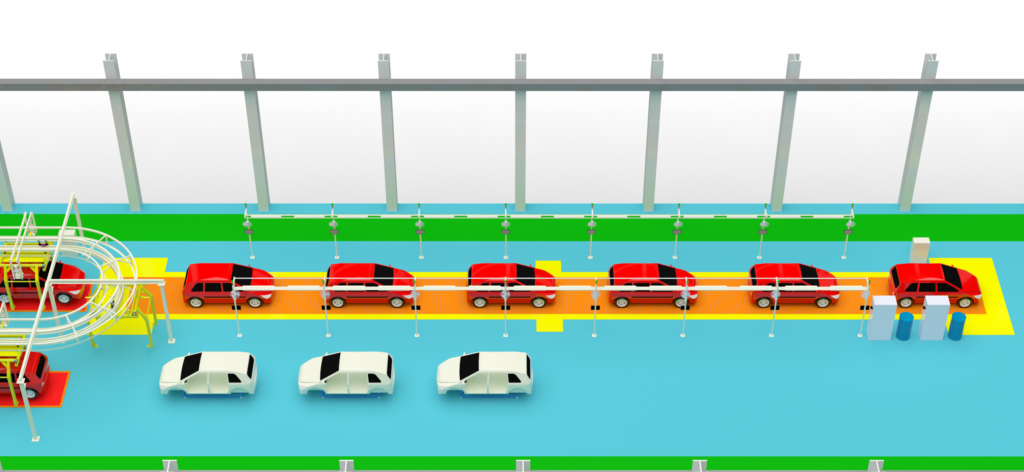

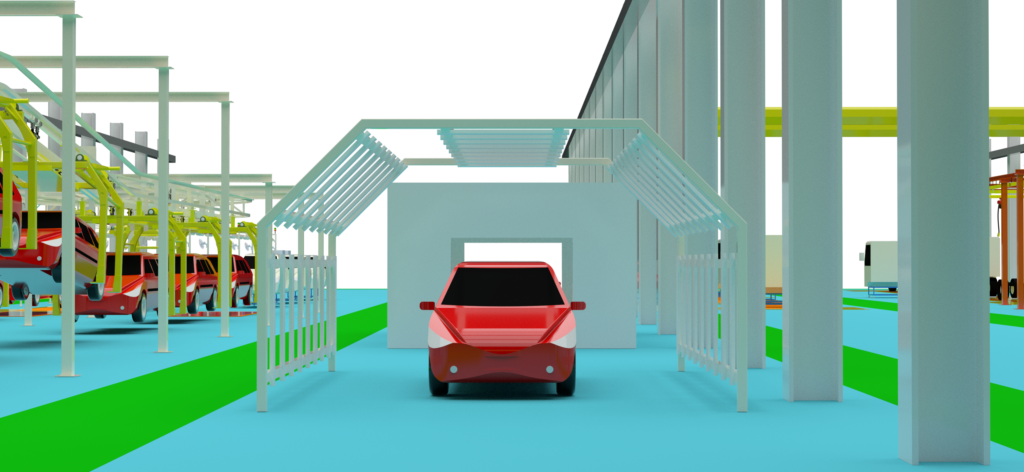

- Body Storage and Interior Assembly: The body is hung on the overhead conveyor chain with a dedicated fixture to complete the first stage of interior assembly, such as installing seats and dashboards.

- Chassis Assembly: The conveyor chain transports the body to the chassis assembly station, where components like the engine, transmission, suspension system, and braking system are installed.

- Secondary Interior Assembly: After the chassis assembly is completed, the body is transferred to the floor-based plate conveyor for secondary interior assembly, such as installing doors and windows.

- Final Inspection and Testing: Once the assembly is complete, the vehicle enters the inspection line for wheel alignment, rain testing, road testing, and other checks to ensure vehicle performance and quality.

- Final Assembly and Storage: After all inspections are completed, the vehicle undergoes final decoration, such as window tinting and floor mat installation, before being stored.

Body-on-Frame Pickup Assembly Line

The assembly line for body-on-frame pickups typically uses a floor-based plate assembly conveyor with a follower frame or a single-chain traction floor track trolley. The workflow is as follows:

- Chassis Pre-assembly: The chassis is pre-assembled to a certain extent outside the assembly line, such as installing some bottom components.

- Chassis Loading: The pre-assembled chassis is hoisted onto the follower frame or trolley on the assembly line.

- Chassis Assembly: On the assembly line, components such as the front and rear axles, engine, transmission, and driveshaft are installed sequentially.

- Body Installation: The body is installed onto the chassis, completing the connection between the body and the chassis.

- Interior and Exterior Assembly: Interior components such as seats and dashboards, as well as exterior components such as tires and lights, are installed.

- Final Inspection and Testing: The vehicle enters the inspection line for wheel alignment, rain testing, road testing, and other checks to ensure vehicle performance and quality.

- Final Assembly and Storage: After all inspections are completed, the vehicle undergoes final decoration, such as window tinting and floor mat installation, before being stored.