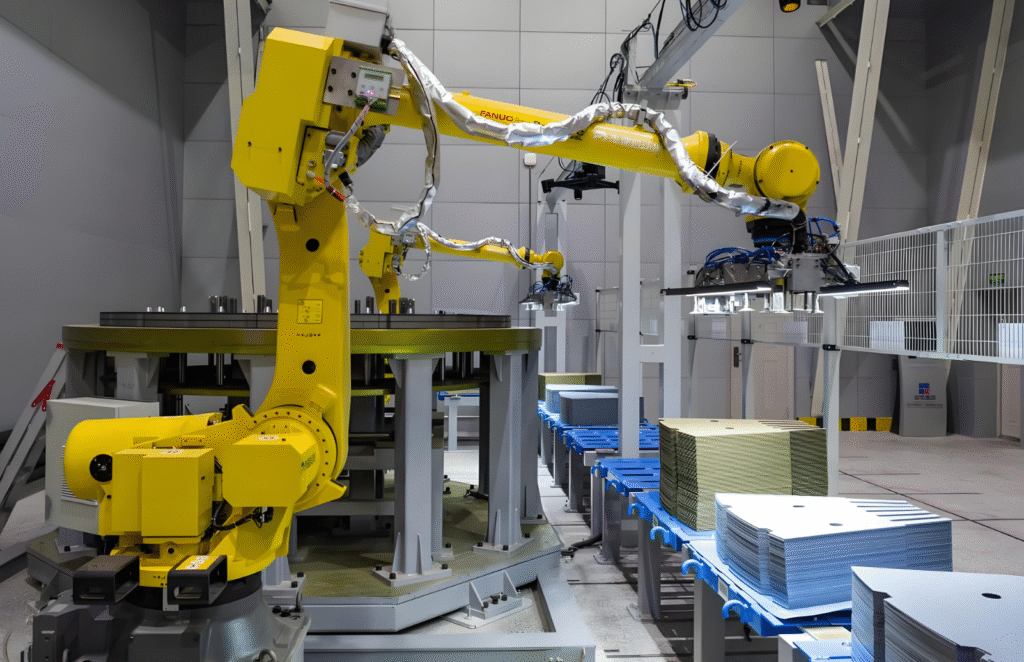

Automatic Stacking Production Equipment for Silicon Steel Sheets Using Industrial Robots

Industrial robot automatic silicon steel sheet stacking equipment is highly efficient and precise, with a high degree of automation. It can adapt to various silicon steel sheet shapes and sizes. The equipment features a robotic arm with an end effector, guide rails, and a control system with sensors and information processing modules. The working process includes feeding, handling, stacking, counting, detecting, and unloading. Regular maintenance, safe operation, and quality control are essential. The equipment should be placed in a suitable environment to ensure its performance.

Features

- High Precision and High Efficiency: The robot, through precise motion control and vision systems, can achieve high-precision silicon steel sheet handling and stacking. Its stacking efficiency is 2 to 3 times that of manual stacking.

- High Degree of Automation: The entire process, from silicon steel sheet feeding, handling, stacking to unloading, can be automatically completed with minimal or no human intervention.

- Strong Adaptability: It can be adjusted and adapted according to different silicon steel sheet shapes, sizes, and stacking process requirements.

- Good Stability: The robot has good stability and repeatability during operation, ensuring the consistency of stacking quality.

- Reduced Labor Intensity: It reduces manual operations and lowers the labor intensity of workers.

Detailed Introduction

- Mechanical Structure:

- Robot Body: Typically a multi-degree-of-freedom robotic arm, such as a six-degree-of-freedom arm, is used to achieve flexible movement.

- End Effector: Depending on the characteristics of the silicon steel sheets, the end effector may be a vacuum suction cup or an electromagnet.

- Guide Rails and Slides: The equipment is equipped with multiple guide rails and slides to achieve linear reciprocating motion of the robotic arm and material troughs.

- Material Trough and Mold: The material trough is used to store silicon steel sheets awaiting stacking, while the stacking mold ensures the neatness of the stacked sheets.

- Control System:

- Controller: A PLC control device is used, which controls the actions of various motors and vacuum generators through programming.

- Sensors: The equipment is equipped with infrared proximity sensors, distance sensors, etc., to detect the position and distance of silicon steel sheets.

- Information Capture and Processing Module: Including an image information acquisition unit, a counting information acquisition unit, and a data processing module. Image and quantity information of silicon steel sheets are obtained through RGB cameras, infrared emitters and receivers, and then processed.

- Working Process:

- Feeding: Silicon steel sheets are conveyed to the material trough by a conveying device.

- Handling and Stacking: The robot, based on the information provided by sensors and vision systems, controls the end effector to accurately grasp the silicon steel sheet and stack it in the designated position.

- Counting and Detection: During the stacking process, the number of stacked sheets is calculated in real time through the counting information acquisition unit, and the position, size, and shape of the silicon steel sheets are detected through the image processing unit.

- Unloading and Placement: After stacking is completed, the stacked silicon steel sheets are unloaded and placed for subsequent operations.

Precautions

- Equipment Maintenance:

- Regularly check the lubrication of robot joints to ensure smooth movement.

- Regularly clean and maintain the end effectors such as vacuum suction cups or electromagnets to ensure their adsorption performance.

- Check the wear of guide rails and slides, and replace worn parts in time.

- Safe Operation:

- During equipment operation, personnel are strictly prohibited from entering its range of motion to prevent accidents.

- Operators should be professionally trained and familiar with the operating procedures and safety regulations of the equipment.

- Quality Control:

- Regularly calibrate the vision system and sensors to ensure their detection accuracy.

- Randomly inspect the stacked silicon steel sheets to check whether their stacking quality meets the requirements.

- Environmental Requirements:

- The equipment should be placed in a clean, dry, and interference-free environment without strong magnetic fields.

- Avoid subjecting the equipment to severe vibrations and impacts.

Applicable Scenarios

- Transformer Manufacturing: In the production of transformers, the quality of silicon steel sheet stacking directly affects the performance and efficiency of the transformer. Automatic silicon steel sheet stacking equipment using robots can precisely stack the sheets, ensuring the tightness and uniformity of the transformer core, thereby enhancing the electrical performance and reliability of the transformer.

- Electric Motor Production: The stators and rotors of electric motors typically require high-precision silicon steel sheet stacking. Automatic stacking equipment with robots can accurately control the position and angle of silicon steel sheet stacking, ensuring the quality of the motor core and improving the efficiency and operational stability of the motor.

- Mass Production: For factories that need to produce a large number of silicon steel sheet stacking products, automatic stacking equipment using robots can achieve a fully automated process, significantly increasing production efficiency and reducing labor costs.

- High Precision Requirements: In applications where extremely high precision of stacking is required, such as the manufacturing of high-end transformers and precision electric motors, automatic stacking equipment with robots can ensure the precise stacking of each sheet through high-precision vision systems and motion control technologies.

Impact on Production Efficiency

- High Degree of Automation: Automatic silicon steel sheet stacking equipment using robots achieves a fully automated process from sheet feeding, grasping, stacking to unloading, reducing human intervention and increasing production efficiency.

- High-Speed Operation: Robots can grasp and stack silicon steel sheets at extremely high speeds, which is 2 to 3 times faster than manual operations, significantly shortening the production cycle.

- Continuous Operation: Robots can work non-stop for 24 hours, unaffected by fatigue or the need for rest, further increasing production efficiency.

- Reduced Human Errors: Through precise programming and control systems, robots reduce the errors that may be caused by human operations, improving production efficiency and product quality.

Impact on Production Quality

- High-Precision Stacking: Using high-precision vision systems and motion control technologies, robots can ensure the precise stacking of each silicon steel sheet, improving the neatness and uniformity of the stack.

- Good Consistency: Robots have good stability and repeatability during operation, ensuring high consistency in the quality of each batch of stacked sheets, thereby improving the overall product quality.

- Quality Inspection: Sensors and information processing modules equipped in the equipment can detect the position, size, and shape of silicon steel sheets in real time during the stacking process, promptly identifying and correcting problems to ensure stacking quality.

- Reduced Defect Rate: Due to the precision and stability of robot operations, the defect rate caused by human factors can be effectively reduced, increasing the product pass rate.

Specific Cases

- A Large Transformer Manufacturing Company: After introducing automatic silicon steel sheet stacking equipment using robots, production efficiency increased by 30%, the defect rate decreased by 20%, product quality was significantly improved, and customer satisfaction was greatly enhanced.

- An Electric Motor Manufacturing Plant: By using automatic silicon steel sheet stacking equipment with robots, the stacking precision of the motor core was improved from ±0.5mm to ±0.1mm, the motor efficiency increased by 5%, and operational stability was significantly enhanced.

In summary, automatic silicon steel sheet stacking equipment using robots has significant advantages in improving production efficiency and product quality, especially suitable for large-scale production scenarios with high precision and quality requirements for stacking.