Selection of Small Motor Assembly Lines

Small motors use compact, lightweight designs: laminated stator stacks, permanent-magnet rotors, die-cast housings and integrated controllers. Assembly sequences—stator winding, rotor balancing, final press-fit and online testing—are highly standardized and fully automated on flexible pallet lines with 30 s takt and 99 % yield. MES schedules orders, downloads parameters, prevents wrong parts, traces every serial number and reports OEE in real time, cutting defects 30 % and raising throughput 20 %.

1. Structural Features of Small Electric Motors

Small motors (e.g., BLDC, stepper, micro-induction) are widely used in consumer electronics, medical devices, and smart-home products. Their mechanical design pursues compact size, light weight, high efficiency, and low cost. Key modules are listed below.

| Module | Composition & Features |

|---|---|

| Stator | Laminated silicon-steel stack with windings. Self-bonding or flyer/needle winding is common to maximize slot-fill and repeatability. |

| Rotor | Usually a permanent-magnet type: magnets are glued or insert-moulded onto the shaft; some use die-cast aluminum squirrel-cage. |

| Housing | Die-cast aluminum or drawn-aluminum shell provides both structural strength and heat dissipation; plastic over-moulding is adopted for cost-down versions. |

| End-shield & Bearings | Miniature motors adopt oil-impregnated or miniature ball bearings; end-shields are plastic or aluminum die-cast for easy automatic assembly. |

| Control PCB (BLDC) | Controller and Hall board are often integrated in one small PCB; EMC, thermal design and assembly space must be considered. |

2. Assembly Process of Small Motors

The process is highly standardized and automation-friendly. A typical flow is:

- Stator Sub-assembly

- Core stacking → Winding (flyer/needle) → Lead welding → Insulation (trickling or dipping) → Electrical test (resistance, surge, hi-pot)

- Rotor Sub-assembly

- Magnet insertion / over-moulding → Dynamic balancing → Bearing press-fit → Magnetizing (if required)

- Final Assembly

- Stator press into housing → Insert rotor → Press end-shields → Screw tightening → Fan / encoder mounting → Air-leak & rotation test

- Test & Packaging

- Electrical run test (no-load current, speed, noise) → Visual inspection → Auto labeling → Packing

Advanced lines reach ≤32 s takt time with ≥99 % first-pass yield.

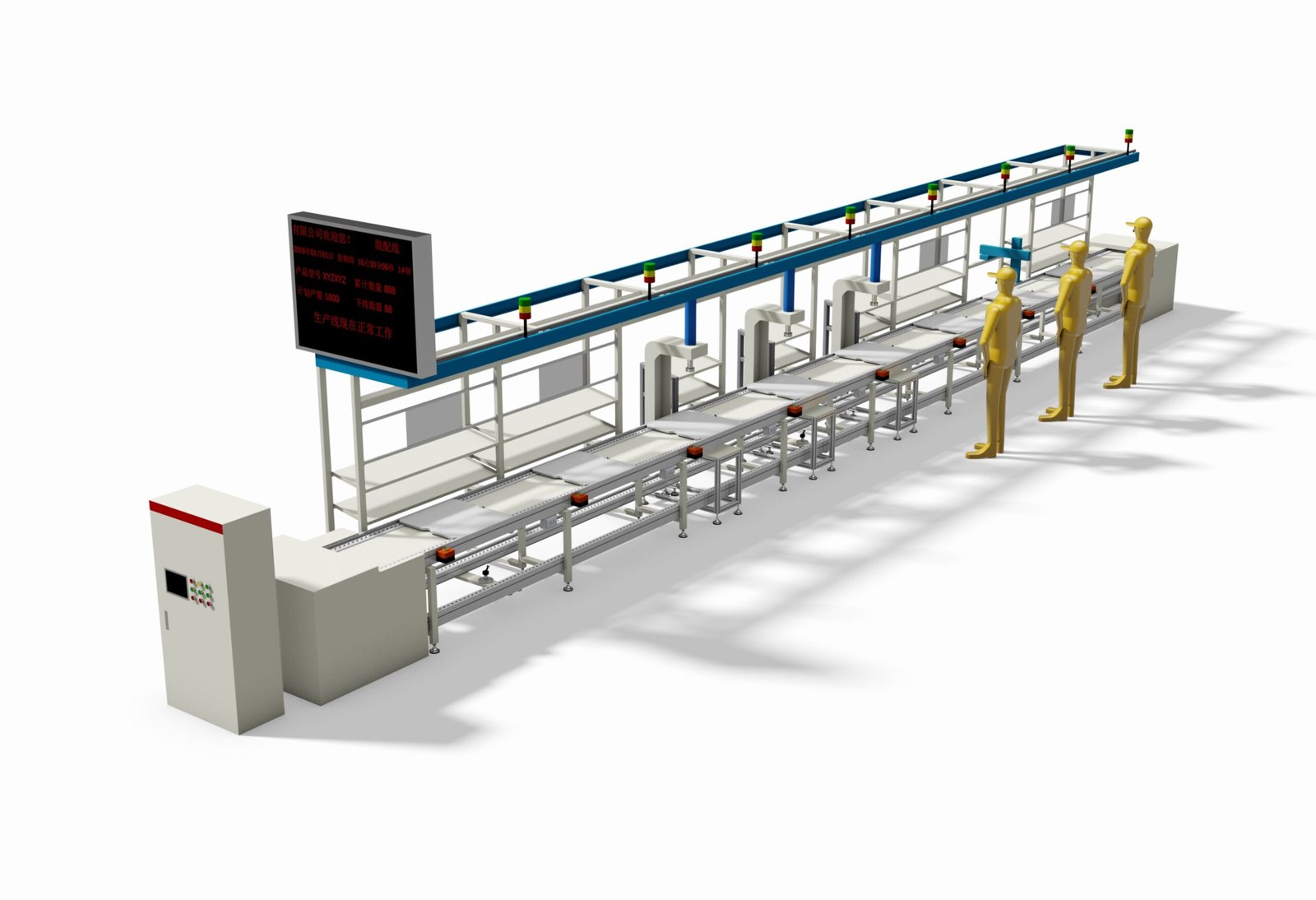

3. Assembly Line Characteristics

Small-motor lines adopt flexible automation:

| Item | Description |

|---|---|

| Conveying | Duplex chain, pallet, or servo-transfer; supports multi-model mixed production. |

| Automation | Auto loading/unloading, pressing, screw-driving, welding, testing; manual assist on a few stations. |

| Takt Control | 30–100 s per piece, adjustable in real time. |

| Flexibility | Quick change-over (0.5–1 h) via modular fixtures. |

| Data Collection | Each pallet carries a unique ID; assembly parameters and test results are logged for single-piece traceability. |

4. MES (Manufacturing Execution System) Integration

MES acts as the “nerve center”, linking planning, process, quality, equipment, and logistics.

4.1 Key Modules & Examples

| Function | Application Example |

|---|---|

| Production Scheduling | Orders automatically sequenced; rush-order & model-change supported; change-over time cut from 25 min to 12 min. |

| Process Management | Electronic SOP, AR guidance, critical parameters (turns, press force) downloaded to machines automatically. |

| Quality Traceability | Each motor gets a unique serial number; full genealogy of materials, parameters, test data, repair history. |

| Error-Proofing | Station scans parts; wrong parts lock machine and alarm; mis-operation rate ↓92 %. |

| Equipment Mgmt. | Real-time OEE monitoring, predictive maintenance (e.g., bearing wear warning). |

| Visualization | KPI dashboards (FPY, defect rate, utilization); daily reports, CPK, SPC analysis. |

4.2 Typical Benefits

- Throughput ↑ ≥20 %

- Defect rate ↓ ≥30 %

- Equipment utilization ↑ 10–15 %

- Change-over time ↓ ≥50 %

- Full traceability from raw material to finished motor

5. Future Trends

- Digital Twin: Virtual model simulates process & takt, identifies bottlenecks before physical start-up.

- AI Visual Inspection: 3-D laser + vision detects rotor scratches or magnet offset; false-negative ≤0.003 %.

- JIT Logistics: MES collaborates with WMS/AGV; parts delivered to line-side by exact takt, reducing inventory.

- Green Manufacturing: Energy-consumption monitoring & peak-valley optimization lower cost of curing ovens, etc.

6. Conclusion

Small-motor manufacturing is rapidly moving toward flexible, automatic and digital production. Combining standardized design, automatic assembly lines and deep MES integration enables high-quality, high-efficiency, fully-traceable smart manufacturing, meeting multi-variety, small-lot market demands and building sustainable competitive advantages.

Feel free to ask for deeper information on equipment selection, MES architecture, or process optimization cases.