Assembly, Painting, and Packaging Lines for Y-Series Asynchronous Motors

The Y-series asynchronous motor features a robust TEFC design with cast or aluminum frames and optimized cooling fins. Its assembly integrates precision press-fitted stator and rotor cores, followed by comprehensive performance testing. An automatic electrostatic painting line applies and cures a durable finish, while an automated packaging line cleans, labels, crates and palletizes each unit, guaranteeing moisture- and shock-proof shipment. The result is a compact, quiet, high-quality motor ready for diverse industrial applications.

1. Structural Features

Y-series asynchronous motors typically feature a totally enclosed, fan-cooled (TEFC) design. They are compact, lightweight, and low-noise. The frame is made of cast iron or aluminum alloy, designed in a square-rounded shape. Cooling fins are arranged both vertically and horizontally to accommodate different weights and cooling requirements.

2. Assembly Process

- Stator Assembly

The stator core is pressed into the frame using an external press-fit process, ensuring the axial position meets drawing specifications. A locking screw is installed to secure the stator core. - Rotor Assembly

The rotor core is directly press-fitted onto the shaft. Methods such as knurled cold press-fit, thermal shrink-fit, or keyed connections are used to ensure reliable bonding between the rotor core and shaft. - Final Assembly

The machined stator, rotor, housing, end shields, and purchased components are assembled together. After assembly, a comprehensive performance test is conducted to ensure the motor meets all specifications.

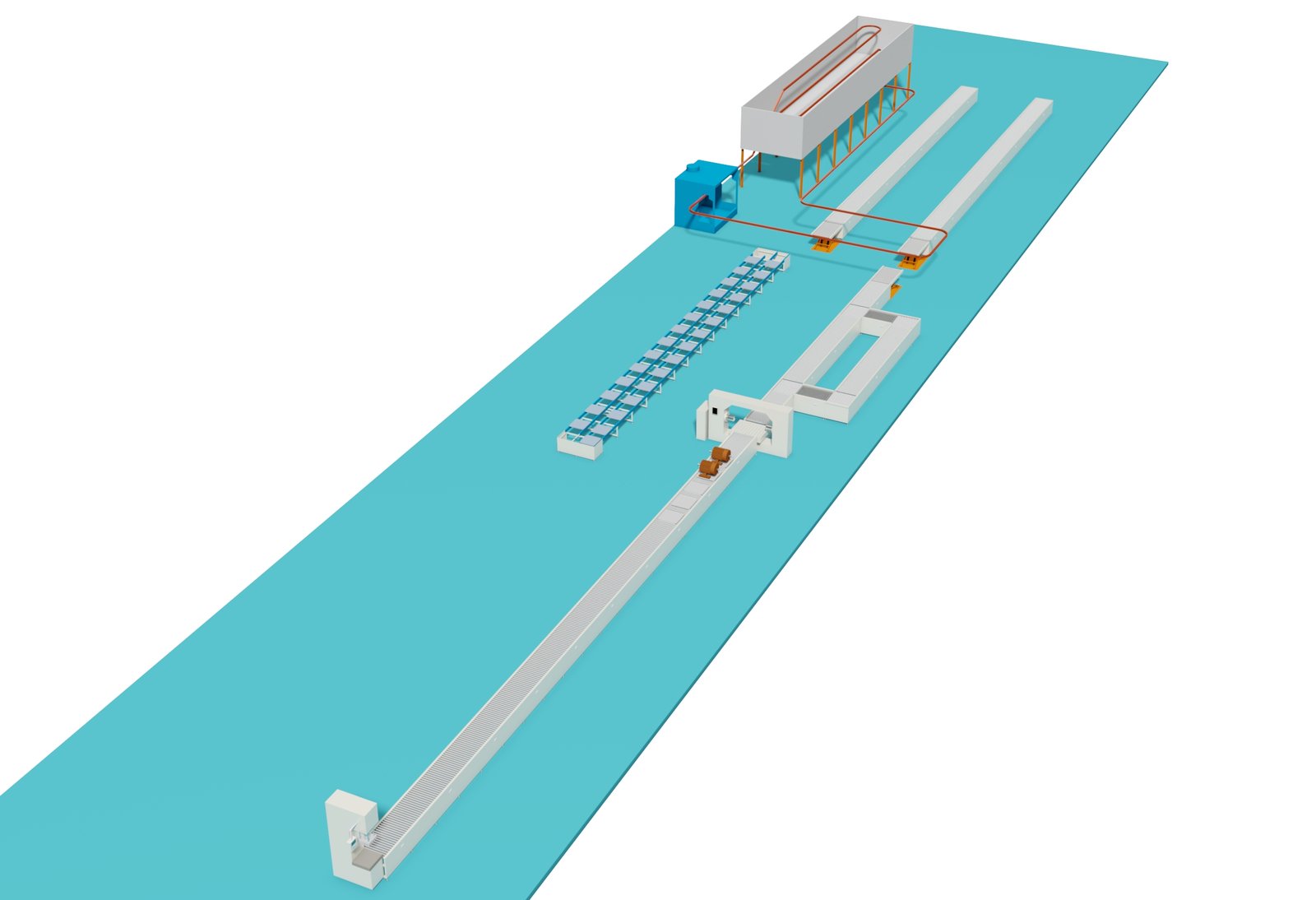

3. Painting Line

- Painting Process

The painting line typically includes automatic electrostatic painting and manual touch-up. Automatic electrostatic painting is used for applying the topcoat to iron housings, while manual touch-up is used to cover any missed areas. - Drying System

After painting, motors enter a drying tunnel for leveling and curing. The tunnel is heated using natural gas, ensuring high coating quality.

4. Packaging Line

- Packaging Requirements

Packaging must protect the motor from moisture and damage during transportation. Wicker crates or fumigated wooden export crates are commonly used to ensure safety during transit and storage. - Automated Packaging

Modern motor packaging lines are equipped with automatic loading/unloading, automatic wrapping, automatic palletizing, and automatic transport systems. This enables full automation from motor off-line to finished packaging, improving efficiency and quality. - Packaging Workflow

The process includes cleaning the motor surface, installing nameplates, fan blades, protective covers, and other accessories. Motors are then boxed, labeled, and sealed. Finally, automatic palletizers stack the packaged motors neatly on pallets for easy transportation and warehousing.

Summary

The production of Y-series asynchronous motors involves precision structural design, strict assembly processes, efficient painting lines, and automated packaging lines. These ensure high-quality, high-performance motor products that meet the demands of various industrial applications.