Key points for PLC-controlled assembly lines

Select PLC by function: list actuators/sensors per station, add 20 % I/O spare, ensure scan ≤ 5 ms for ≤ 1 s takt, pick EtherCAT/Profinet if > 30 m or MES link, choose relay/transistor outputs by load, verify special modules early. Program in four layers: SFC flow, FC stations, FB devices, independent safety; double-interlock every output, timeout cylinders, position+time check conveyors, stop upstream only on fault, demand Quality-OK before release, keep data retentive. Split fast/slow tasks, queue pallets for parallel stations, commission single-step, E-stop, sensor-loss and 120 % takt tests.

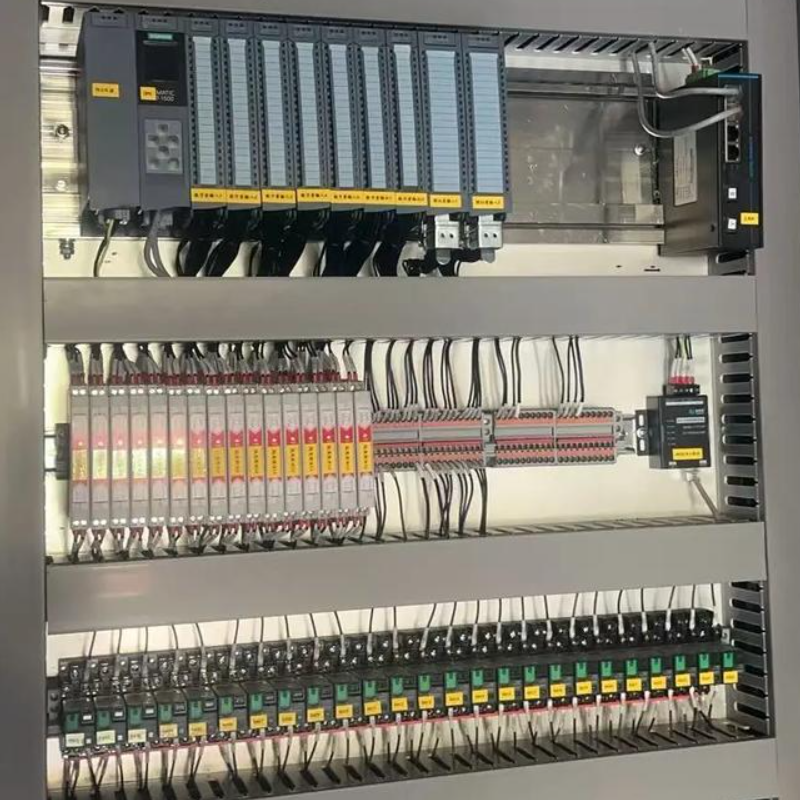

Key Points for PLC-Controlled Assembly Lines

A detailed, generic guide on how to select a PLC and design its program according to the functions of an assembly conveyor.

- Hardware Selection – 7 Steps, Function First

(Valid for any brand; do not change the order)

1.1 Translate the process into an “Action List”

- Count how many stations must be inter-locked

- List every actuator (cylinder, servo, VFD, robot) and every sensor (photo, prox, pressure, vision OK/NG) per station

- Note special modules (weighing, temperature, barcode, vision, RFID)

These numbers decide I/O count and field-bus type later [5, 12]

1.2 Count I/O and add spare

Digital In = sensor count × 1.2

Digital Out = actuator count × 1.2

Analog In/Out = 1-2 per station as a rule of thumb

High-speed inputs for encoders or color marks ≥ 50 kHz

Add 10 % spare on top of the above [14]

1.3 Choose CPU – scan time first, memory second

If takt ≤ 1 s, keep scan ≤ 5 ms

Estimate program size: 100 steps per station × number of stations × 2 (fault & inter-lock) × 1.5 safety factor

Memory = steps × 5 B with 30 % free left [11]

1.4 Choose field-bus – driven by distance

< 30 m single rack: local I/O enough

30 m or > 4 remote drops: use EtherCAT, Profinet, CC-Link IE, etc.

If MES/SCADA connection is required, CPU must supply OPC-UA or MQTT [6, 13]

1.5 Choose output type – driven by actuator

Relay: high-current contactors or 24 V/220 V solenoids, life 1 M ops

Transistor: DC solenoids, servo pulses, < 1 ms response

Triac: AC power-regulation, heaters [14]

1.6 List special modules once

High-speed counter (color mark, encoder), weighing module, vision trigger, temperature PID, safety module (Cat. 3 / PLe)

Confirm the PLC family can host them before you freeze the model [11]

1.7 TCO check – not only hardware price

Add software licence, bus cables, start-up training, future expansion racks

Check team skill – a ladder-only crew will hate a high-end IEC-61131-3 ST-only platform [6]

- Software Design – 4-Layer Skeleton + 6 Universal Rules

(Works for any brand or process)

2.1 Draw the 4-layer skeleton

Layer 1 – Flow (SFC): Power-on → Home → Auto-cycle → Stop → E-stop

Layer 2 – Station (FC): one sub-routine per station; entry = previous done + local free + no fault

Layer 3 – Device (FB): cylinder, servo, VFD, robot each wrapped in an FB exposing only Start/Stop/Fault pins

Layer 4 – Safety (FBD): E-stop, light curtain, gate, two-hand button – highest priority, independent task [10, 13]

2.2 Six universal rules

- Every output gets a double inter-lock inside its FB – software condition AND hardware feedback

- Give every cylinder an “action-timeout” timer; 2 s overrun → fault & stop

- Conveyor uses “position + time” double check – limit switch + timer to detect a jammed pallet [5]

- Any station fault stops only upstream, not downstream, to avoid scrap

- Critical stations (press-fit, weld, screw) must receive a Quality-OK signal before release; otherwise mark NG and divert

- Keep timers, counters and HMI set-points in retentive memory so they survive power-loss [8]

2.3 Takt-time optimisation tricks

- Split scan tasks – 2 ms fast task (servo pulses, safety) and 10 ms slow task (HMI, reporting)

- When stations run in parallel, buffer pallet IDs in a FIFO queue; fill every empty slot to remove idle time [10]

- For long tasks (servo tighten, robot transfer) use step-number + interrupt so PLC scan never stalls

2.4 Commissioning checklist (tick when done)

□ Single-step / single-cycle / dry-run modes all OK

□ Random E-stop at three places – all outputs OFF within 500 ms

□ Pull any sensor – HMI shows “XXX lost” within 1 s

□ Run at 120 % takt for 2 h – CPU scan still < 5 ms

□ 10 power-cycle tests – production data kept, queue not corrupted

One-sentence wrap-up

Selection: “specials first, generics later” – lock bus, high-speed, analog, safety, then pick CPU by I/O count

Programming: “skeleton first, details later” – SFC for flow, FB for devices, double inter-lock for safety, takt & queue for throughput

Follow these two parts and any assembly-line PLC system will be right the first time, easy to expand, and painless to maintain.