Types of Photovoltaic Cells and PV Module Assembly Production line

Photovoltaic cells come in various types and sizes, such as monocrystalline silicon cells with popular dimensions like 166mm, 182mm, and 210mm, each offering different efficiencies and power outputs. Polycrystalline cells are also common, with slightly lower efficiencies but cost advantages. Advanced technologies like PERC, TOPCon, and HJT further enhance cell efficiency. The production of photovoltaic modules involves a series of processes, including cell sorting, laser cutting, string soldering, lamination, framing, and testing, supported by specialized equipment. Modern module production lines are highly automated and can handle different cell sizes and module types, with capacities reaching up to 750MW annually. The trend is toward larger cells and higher efficiency to meet growing market demands.

Types of Photovoltaic (PV) Cells and Their Specifications

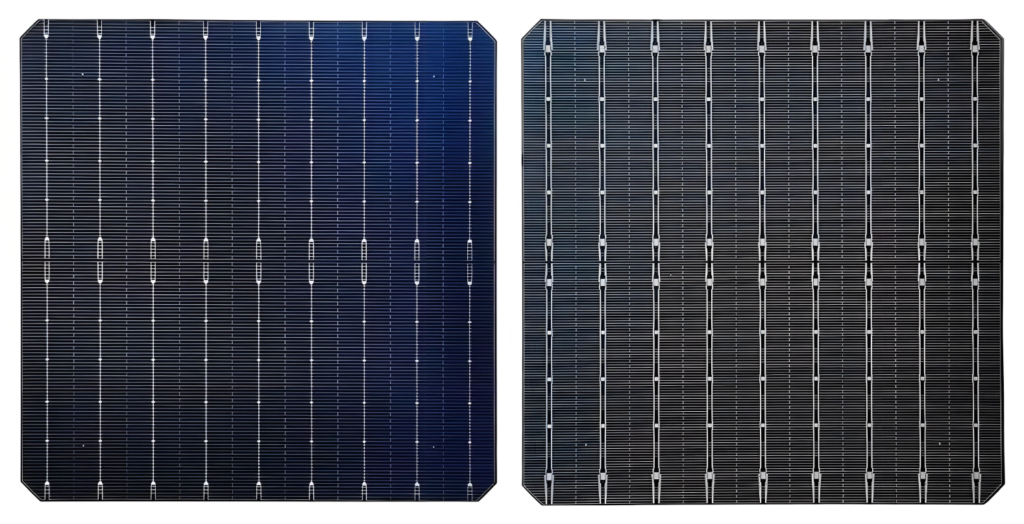

1. Monocrystalline Silicon Cells

- 166mm Cells

- Dimensions: 166mm × 166mm

- Efficiency: Approximately 20% – 22%

- Power (per cell): About 5.2 – 5.5W

- Applications: Suitable for traditional 60-cell or 72-cell modules, commonly used in residential and small commercial installations.

- 182mm Cells

- Dimensions: 182mm × 182mm

- Efficiency: Approximately 21% – 23%

- Power (per cell): About 6.8 – 7.0W

- Applications: Suitable for most PV modules on the market, and are one of the most popular sizes. They offer a good balance of high efficiency and adaptability, making them ideal for large-scale power plants and commercial applications.

- 210mm Cells

- Dimensions: 210mm × 210mm

- Efficiency: Approximately 21.5% – 23.5%

- Power (per cell): About 8.6 – 8.9W

- Applications: Often used in ultra-high-power modules, suitable for large-scale photovoltaic power stations.

2. Polycrystalline Silicon Cells

- Dimensions: Commonly similar to monocrystalline cells, such as 166mm, 182mm, etc.

- Efficiency: About 17% – 19%

- Characteristics: Lower cost, suitable for budget-sensitive projects.

3. Advanced Technology Cells (e.g., PERC, TOPCon, HJT)

- Dimensions: Typically larger cells, such as 182mm, 210mm.

- Efficiency: PERC technology efficiency is around 20% – 22%, while TOPCon and HJT technologies offer higher efficiencies, reaching above 23%.

- Power: Module power can be increased to over 500W.

Photovoltaic Module Production Line

The photovoltaic module production line is the process of encapsulating photovoltaic cells into modules that can be directly used for power generation. Below are the main processes and equipment of the photovoltaic module production line:

1. Production Process

- Cell Sorting: Classify cells based on performance to ensure consistency within the module.

- Laser Cutting: Cut cells into desired shapes (e.g., for half-cut modules).

- String Soldering: Use soldering ribbons to connect cells in series, forming cell strings.

- Lamination: Stack cells, glass, EVA, backsheet, and other materials in sequence.

- Pressing: Vacuum and heat are applied to melt the EVA, bonding the layers together.

- Trimming: Remove excess EVA from the edges of the module.

- Framing: Install aluminum frames to protect the module and facilitate installation.

- Junction Box Installation: Attach junction boxes to connect and protect the module’s electrical circuit.

- Curing: Allow the sealant to cure, enhancing the module’s seal.

- Testing: Includes insulation voltage testing, grounding continuity testing, IV testing, etc.

- Cleaning: Clean the surface of the module to remove dust and impurities.

- Packaging: Package the modules for shipping.

2. Main Equipment

- Laser Cutting Machine: For cutting cells.

- String Soldering Machine: For connecting cells in series.

- Automatic Layering Equipment: For stacking materials.

- Laminator: For the lamination process.

- Automatic Frame and Edge Trimming Machine: For installing frames.

- Junction Box Welding Machine: For attaching junction boxes.

- EL Tester: For detecting hidden cracks in cells.

- IV Curve Tester: For testing the electrical performance of modules.

3. Characteristics of the Production Line

- Capacity: For example, a 750MW production line has an annual capacity of 750MW, producing 190 modules per hour.

- Automation: Modern production lines are highly automated, reducing manual operations and improving production efficiency and product quality.

- Compatibility: Capable of accommodating different sizes and types of modules.

Summary

The specifications and types of photovoltaic cells have a significant impact on their performance and application scope, while the photovoltaic module production line, through a series of complex processes and equipment, encapsulates cells into modules that can be directly used for power generation. With the development of technology, larger and higher-efficiency cells and module production lines are increasingly favored in the market.