Design and Manufacture of Laser Welding Equipment for Automotive Components

The design and manufacture of laser welding equipment for automotive components involve creating a mobile support structure with clamping mechanisms and integrating a welding head with robotic arms for flexibility. Technical parameters such as laser power (50W–4kW), welding speed (0.1–10m/min), weld width and depth (0.1–5mm), and precision (±0.1–±0.5mm) are carefully set. The equipment is used for welding automotive bodies, structural components, powertrain parts, and new energy vehicle components. High-precision machining and automated assembly ensure reliability. Parameter optimization and protective gas systems enhance welding quality. The equipment supports lightweight and high-strength applications, contributing to vehicle safety and efficiency.

Design and Manufacture of Laser Welding Equipment for Automotive Components

I. Design

- Equipment Structure Design:

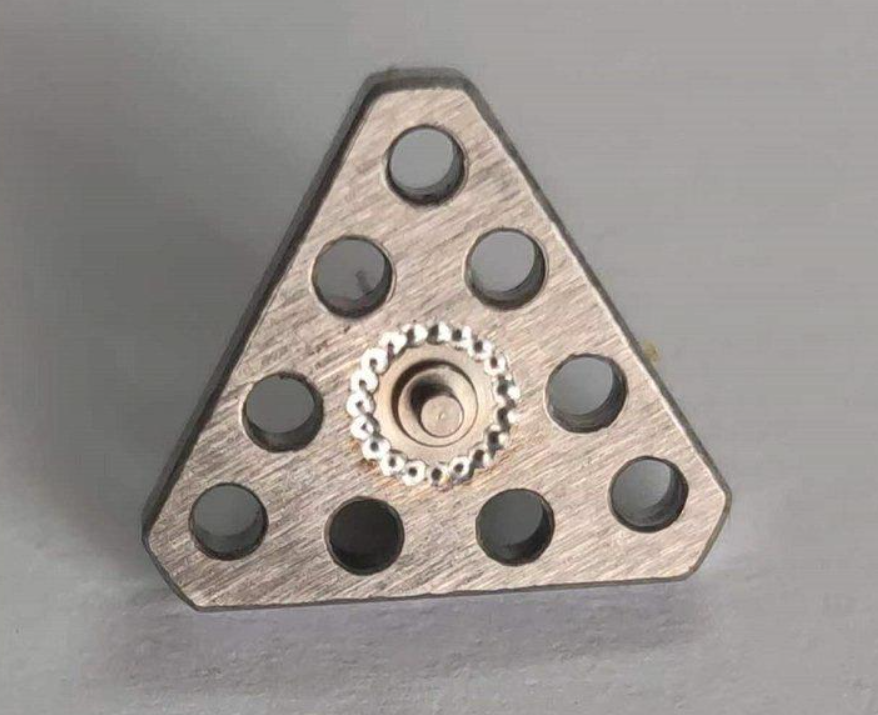

- Mobile Support Mechanism: It includes a support base and four clamping and fixing mechanisms, with mobile cushioning mechanisms evenly distributed around the bottom.

- Welding Head Integration: The laser welding equipment typically integrates the welding head with a robotic arm for flexible operation.

- Technical Parameter Design:

- Laser Power: The power range is generally from 50W to 4kW, depending on the thickness and type of the welding material.

- Welding Speed: The speed range is from 0.1m/min to 10m/min.

- Weld Width and Depth: The width and depth are usually between 0.1mm and 5mm.

- Welding Precision: The precision range is from ±0.1mm to ±0.5mm.

- Defocusing Amount: Positive and negative defocusing are adjustable, with negative defocusing providing greater penetration depth.

- Pulse Parameters: Pulse duration, frequency, and peak power are adjustable, with short pulses suitable for small and complex welding.

II. Manufacture

- Manufacturing Process:

- High-Precision Machining: Ensuring the precision of the welding head and mobile support mechanism.

- Automated Assembly: Enhancing the stability and reliability of the equipment.

- Equipment Commissioning:

- Parameter Optimization: Adjusting laser power, welding speed, and other parameters according to actual welding requirements.

- Protective Gas System: Using inert gases to expel plasma and protect welding quality.

III. Technical Parameter Table

| Parameter | Unit | Value Range | Notes |

|---|---|---|---|

| Laser Power | W | 50-4000 | Adjusted according to the thickness and type of welding material |

| Welding Speed | m/min | 0.1-10 | Adjusted according to the welding material and plan |

| Weld Width | mm | 0.1-5 | Adjusted according to the welding material and plan |

| Welding Depth | mm | 0.1-5 | Adjusted according to the welding material and plan |

| Welding Precision | mm | ±0.1-±0.5 | Adjusted according to the welding material and plan |

| Defocusing Amount | mm | Adjustable positive and negative | Negative defocusing provides greater penetration depth |

| Pulse Width | ms | Adjusted according to material | Short pulses are suitable for small and complex welding |

IV. Application

- Automotive Body Welding: Used for welding different parts of the body, such as the trunk lid, door inner panel, etc.

- Body Laser Assembly Welding: Used for welding sub-assemblies or assemblies of the white body to increase body stiffness.

- Typical Components: Such as intake and exhaust valves, clutches, bumpers, etc., to meet the requirements of high strength and lightweight.

- New Energy Vehicle Key Components: Precision welding of battery packs and air outlets to meet the requirements of lightweight and high strength.

V. Application Scope Table

| Application Scope | Specific Use |

|---|---|

| Automotive Body | Laser welding of roof, trunk lid, frame, etc. |

| Body Structural Components | Laser welding of doors, body side frames, pillars, etc. |

| Variable Thickness Laser Welded Blanks | Used for body side frames, door inner panels, windshield frames, wheel arch panels, floor panels, center pillars, etc. |

| Powertrain Components | Welding of drive shafts, exhaust pipes, etc. |

| New Energy Vehicle Components | Welding of batteries and air outlets, sensors and electronic units, etc. |

| Other Components | High-voltage relays, filters, torque sensors, turbochargers, fuel rails, cylinder gaskets, spark plugs, segmented motor stators, seat adjustment screws, airbags, etc. |

VI. Development Trends

- Automation and Intelligence: Using computer control and robotic technology to improve production efficiency and welding quality.

- High Precision and High Efficiency: Continuously optimizing welding process parameters to enhance equipment performance.

- Lightweight and High Strength: Reducing vehicle weight and improving the integration and safety performance of the body through laser welding technology.