General process requirements for customizing product assembly lines

Customizing a product assembly line follows a structured seven-step process: requirement analysis, preliminary design, drawing approval, precision manufacturing, on-site installation, trial-run acceptance, and after-sales support. Each phase is customer-driven, balancing throughput targets, automation level, space constraints and budget. Designs specify line layout, conveyor type, workstation number, control architecture and safety systems. Parts are machined, tested, then shipped for modular installation; PLC programs are tuned until cycle times meet takt requirements. Trial production verifies yield, availability and operator ergonomics before sign-off. Complete documentation, training and spare-part contracts secure long-term OEE.

1. Requirement Analysis and Objective Definition

This is the starting point of the entire customization process and determines the direction and depth of the subsequent design.

Key elements include:

- Product structure, dimensions, weight, and process flow

- Production capacity targets (e.g., output per hour)

- Automation level (manual, semi-automatic, or fully automatic)

- Operating environment (e.g., space constraints, temperature/humidity, cleanliness)

- Existing production line conditions (whether integration with legacy equipment is needed)

Clearly defining requirements is critical to ensuring the design is practical and avoiding costly rework later.

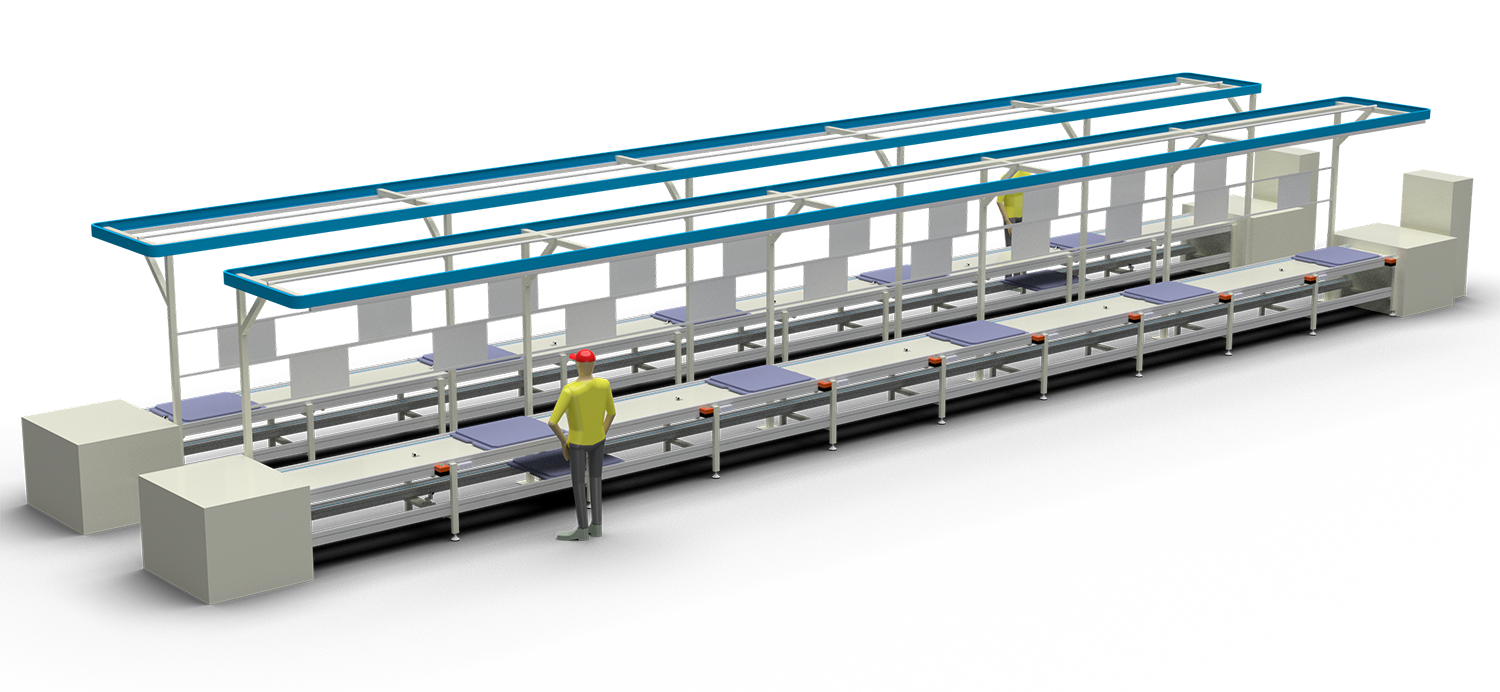

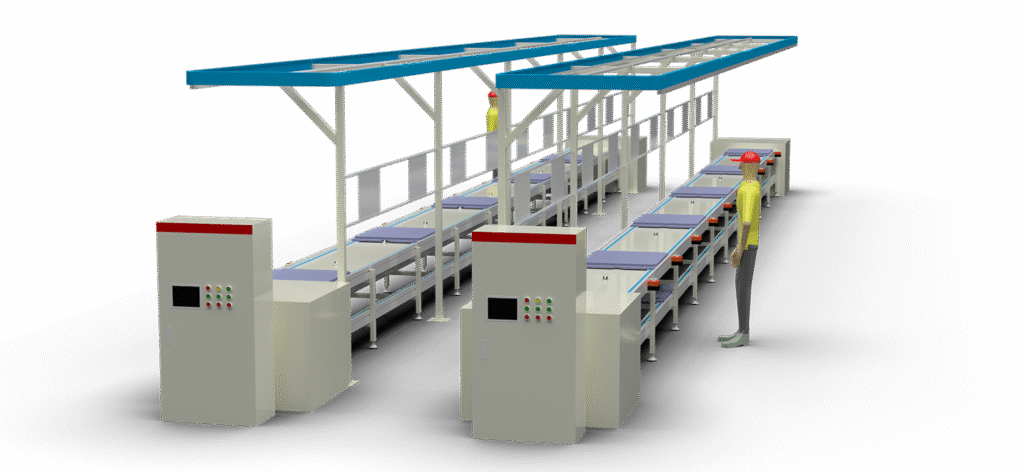

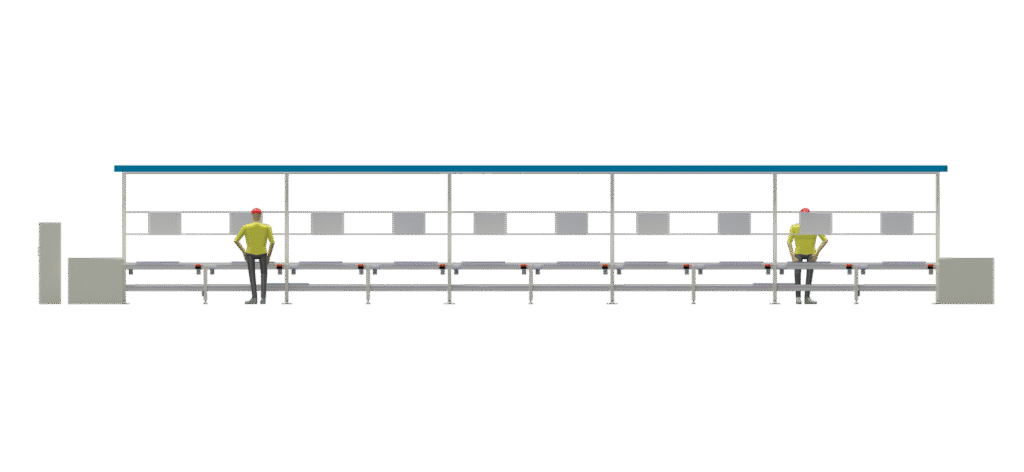

2. Preliminary Design and Planning

Based on the requirement analysis, the overall and detailed structure of the assembly line is designed.

Design elements include:

- Selection of line type (straight, U-shaped, rotary, recirculating, etc.)

- Number and layout of workstations (parallel stations, buffer zones)

- Conveying method (belt, chain, roller, double-speed chain)

- Selection of automation equipment (robots, automatic assembly machines, vision systems)

- Control system architecture (PLC, sensors, MES interface)

The design must balance cost-effectiveness, scalability, and maintainability.

3. Drawing Preparation and Technical Confirmation

The design is translated into detailed drawings and technical documents for manufacturing and assembly.

Includes:

- General assembly and part drawings

- Bill of Materials (BOM)

- Electrical schematics and wiring diagrams

- Pneumatic/hydraulic schematics

- Installation and commissioning manuals

Drawings must be reviewed and approved by the customer to ensure accuracy and completeness.

4. Manufacturing and Quality Control

Parts are machined, procured, and pre-assembled according to the drawings.

Key steps:

- Precision machining (cutting, drilling, tapping)

- Custom fabrication and surface treatment of non-standard parts

- Verification of key component brands and quality (motors, sensors, etc.)

- Functional testing and quality inspection before shipment

Strict quality control must be enforced during manufacturing to ensure the delivered equipment meets design specifications.

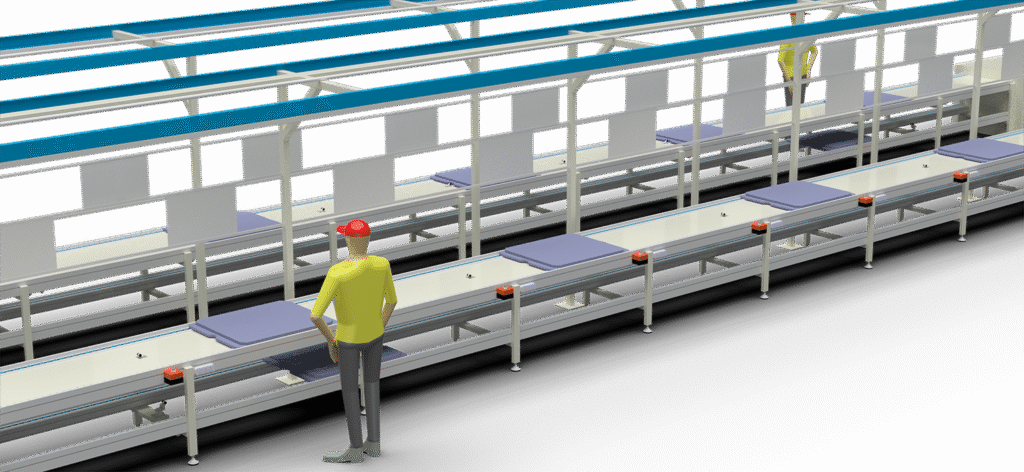

5. On-Site Installation and Commissioning

The assembled equipment is delivered and installed at the customer’s site.

Main tasks:

- Equipment positioning and anchoring

- Electrical wiring and pneumatic connections

- Control system debugging and parameter setting

- Workstation cycle time testing and bottleneck optimization

- Installation and verification of safety devices (emergency stops, guards, etc.)

Close collaboration with the customer’s production team is essential to ensure smooth startup.

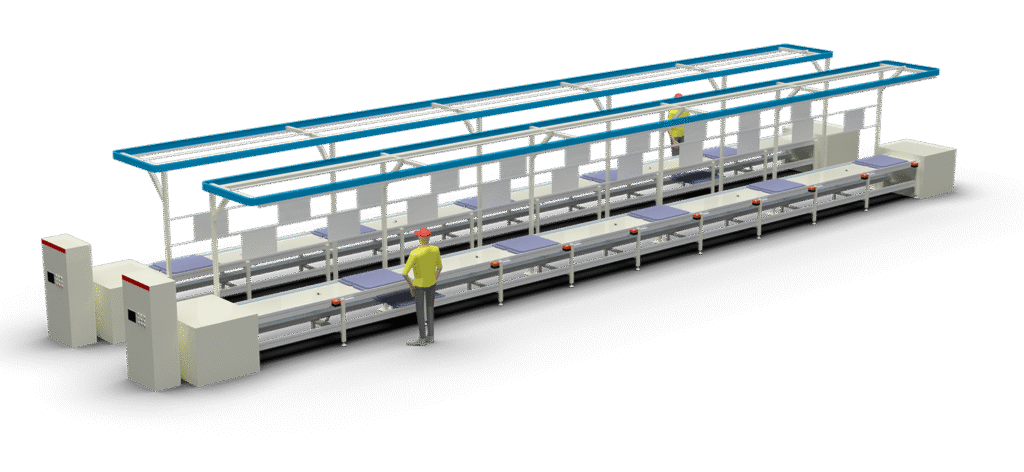

6. Trial Production and Acceptance

Before full production, trial runs are conducted to verify line stability and capacity.

Acceptance criteria include:

- Product yield and consistency

- Balanced cycle times across workstations

- Stability of automation equipment

- Failure rate and emergency response capability

Also includes:

- Operator training (equipment use, daily maintenance, safety procedures)

- Provision of operation manuals, maintenance guides, and troubleshooting charts

Formal acceptance and handover occur only after successful trial production.

7. Project Summary and After-Sales Support

After delivery, the project is documented and archived for future maintenance and upgrades.

Includes:

- Archiving technical documents (drawings, manuals, acceptance reports)

- Project summary report (issues and improvement suggestions)

- After-sales service arrangement (regular follow-ups, remote support, spare parts supply)

Reliable after-sales support is key to ensuring long-term stable operation.

Summary:

Customizing a product assembly line is a highly coordinated, phase-driven systems engineering process, spanning from requirement analysis to after-sales service. Success depends on:

- Clear upfront requirements

- Scientific and rational design

- Controllable manufacturing and installation quality

- Rigorous commissioning and acceptance

- Effective training and support

Companies should choose experienced equipment suppliers and establish cross-functional project teams to ensure the custom line is successfully implemented and delivers value.