Laser Cleaning Equipment for Engines

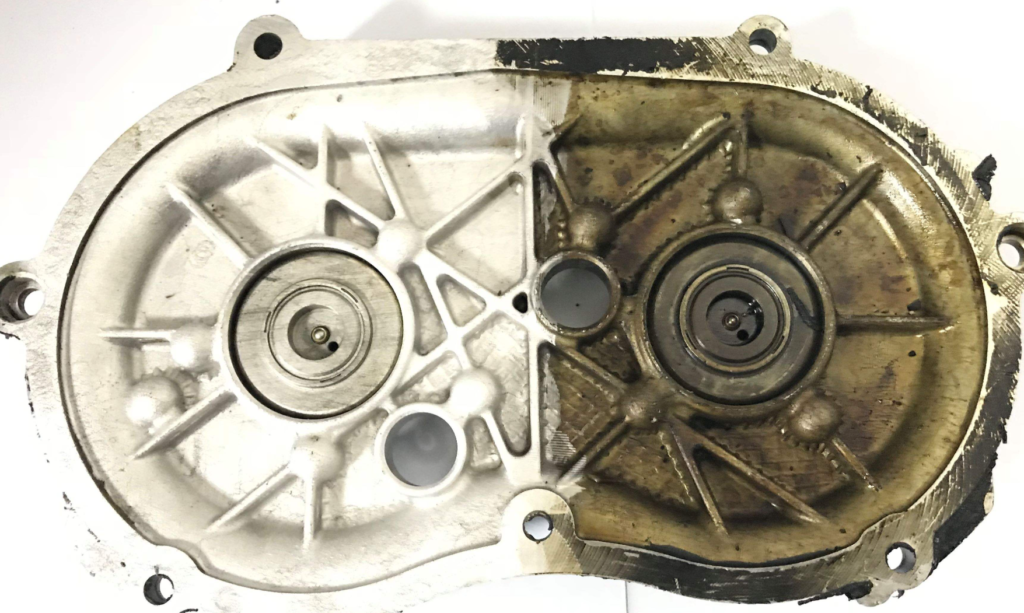

Laser cleaning equipment for engines is a highly efficient and environmentally friendly tool used to remove contaminants such as rust, oil, and carbon deposits from engine components. This non-contact cleaning method uses high-energy laser beams to precisely target and vaporize pollutants without damaging the underlying materials. It is suitable for various engine parts, including cylinder heads, pistons, and exhaust manifolds, and can be applied without disassembly. Compared to traditional methods, laser cleaning is faster, safer, and produces no hazardous waste. Available in both handheld and fixed configurations, it offers flexibility and precision, making it an ideal solution for maintaining engine performance and longevity while reducing maintenance time and environmental impact.

Laser cleaning equipment for engines is a cutting-edge technology that uses high-energy laser beams to remove contaminants such as oil, grease, rust, and carbon deposits from engine components. This non-contact and non-abrasive method is highly precise and environmentally friendly, making it an ideal solution for maintaining engine performance and longevity.

Main Features

- Non-Destructive Cleaning: Laser cleaning removes contaminants without physically touching the engine parts, eliminating the risk of damage.

- Precision Control: The laser parameters can be adjusted to target specific contaminants while preserving the underlying materials.

- Environmentally Friendly: Unlike traditional chemical cleaning methods, laser cleaning does not produce hazardous waste or emissions.

- Efficiency: Laser cleaning is faster and more effective than traditional methods, reducing maintenance downtime.

- Versatility: Suitable for various engine materials, including metals, plastics, and composites.

Applications

- Cylinder Heads and Pistons: Removes carbon deposits to improve fuel efficiency and engine performance.

- Engine Blocks: Cleans rust and contaminants to extend engine lifespan.

- Exhaust Manifolds: Removes carbon deposits to optimize exhaust flow.

- Turbochargers: Restores functionality and enhances overall engine performance.

Advantages Over Traditional Methods

- No Chemicals: Reduces environmental impact and eliminates the need for hazardous chemical solvents.

- No Disassembly Required: Cleans assembled components directly, saving time and labor costs.

- Flexibility: Can be used on-site or outdoors without the need for a specialized cleaning room.

Equipment Options

Laser cleaning equipment for engines is available in various configurations, including handheld and fixed systems. These devices offer different power options (e.g., 200W to 1000W) and cleaning modes (manual or automatic) to suit specific maintenance needs.

Conclusion

Laser cleaning equipment for engines represents a significant advancement in automotive maintenance. Its precision, efficiency, and eco-friendly nature make it a valuable tool for ensuring optimal engine performance while reducing maintenance costs and environmental impact.