What are the common equipment and supporting facilities in an assembly workshop?

An assembly workshop typically needs equipment grouped by six process steps: receiving, pre-treatment, sub-assembly, final assembly, inspection and packaging. Core machines include dock levelers, ultrasonic cleaners, differential-chain conveyors, servo presses, AGVs, six-axis robots, CMMs and automatic cartoners. Utilities cover screw compressors, chillers, PSA nitrogen, HVAC with FFUs, and fire-sprinkler systems. Must-have items satisfy 80 % of capacity; optional units such as vision-guided robots or robotic palletizers can be added later. Selecting local suppliers, open-protocol controls and simultaneous design of environmental facilities shorten payback and ensure EIA approval.

1. Classification logic

a. Follow the technological flow: logistics receiving → parts pre-treatment → sub-assembly → final assembly & debug → inspection → packaging & shipping.

b. For each stage, distinguish three sub-categories: core production machines, auxiliary tooling, and utility/environmental facilities—18 sub-groups in total that cover ≥90 % of normal needs.

c. Indicate “must-have vs. optional”, “local or imported acceptable”, and “example brand/spec” so that re-selection time is minimized.

2. Detailed description

1) Logistics receiving area

- Functions: unloading, unboxing, rough de-dusting, buffer storage.

- Core machines: hydraulic dock leveler (1.5 t, 1.1 × 2.0 m), handheld barcode scanner, mobile dock ramp.

- Auxiliary: canopy, crash barrier, outdoor LED display (shows call number), negative-pressure dust extraction nozzle (prevents dust while unboxing).

2) Parts pre-treatment area

- Functions: degreasing, deburring, anti-rust, drying.

- Core machines: ultrasonic cleaner (28 kHz, 300 L tank), pass-through spray washer (0.8 m mesh belt), hot-air circulation oven (120 °C, 4 trolleys).

- Tooling/instrument: ESD parts trolley, on-site cleanliness meter (particle counter).

- Environmental: wash wastewater collected → oil separator + DAF → discharge; VOC from solvent recovered by condensation unit.

3) Sub-assembly (synchronous pallet line)

- Function: pre-assemble parts into modules, takt 30–60 s.

- Core machines:

– Differential chain conveyor (2 × speed, aluminium frame, 24 m, reversible)

– Pneumatic torque driver (0.5–12 N·m, with angle monitoring)

– Servo press (5 kN, position ±0.01 mm, force-displacement curve stored) - Tooling: quick-change fixture pallet (±0.05 mm location), MES terminal (program pops up after scan).

- Auxiliary: cantilever balancer (50 kg, 2.5 m arm), local laminar hood (class 100, 0.3 m/s face velocity).

4) Final assembly & debug (off-line stations + in-line test)

- Function: integrate modules into finished unit and verify functions.

- Core machines:

– AGV feeding cart (magnetic/QR hybrid, 800 kg)

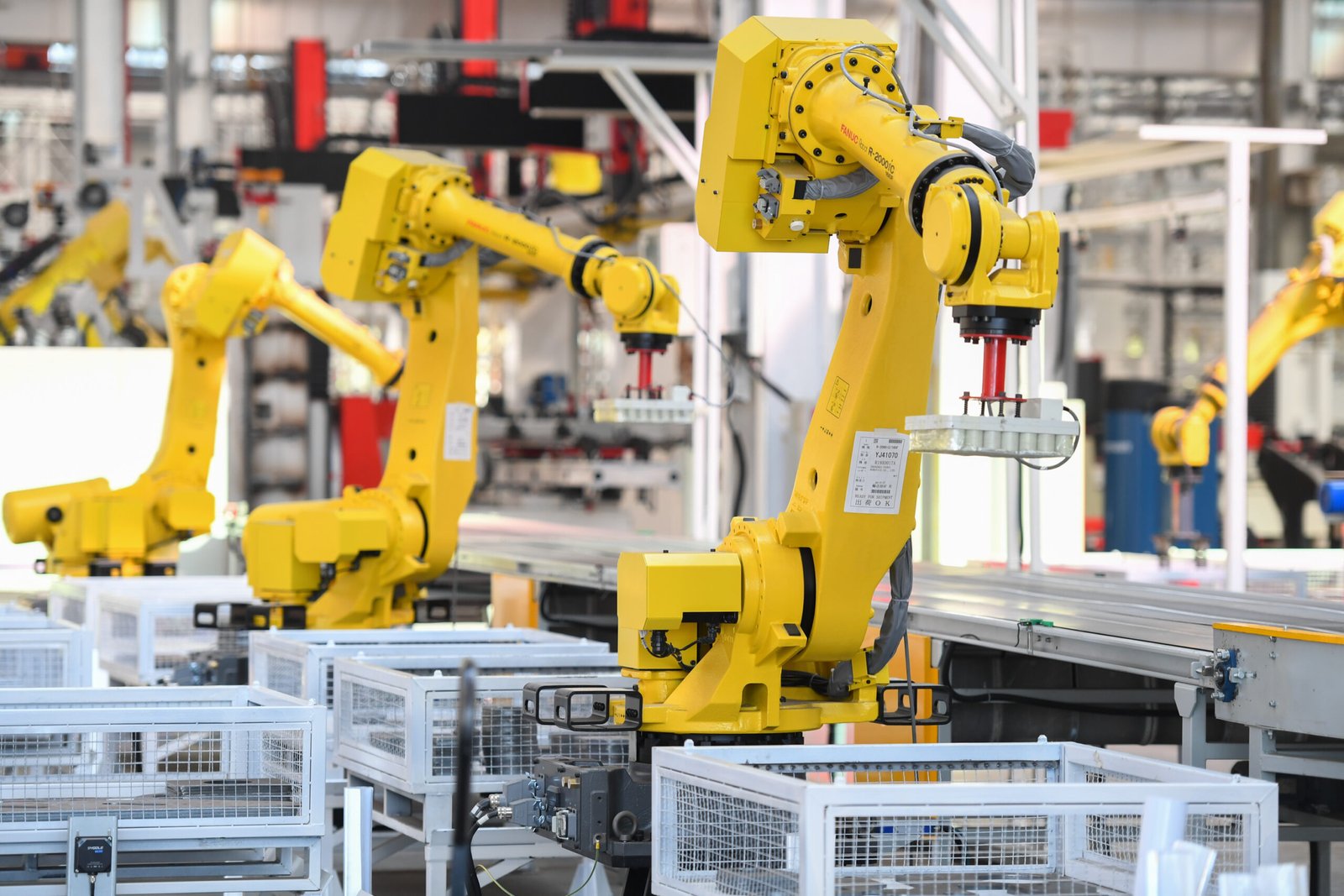

– 6-axis screw-driving robot (repeatability ±0.02 mm, with vision)

– Motorised lift & rotate table (Ø 1.2 m, 500 kg, free-angle stop) - Instruments:

– Hi-pot tester (AC 5 kV / DC 6 kV)

– Laser shaft alignment tool (for drive-line) - Auxiliary: silence room (≤65 dB) + extraction arm (for welding/adhesive fumes).

5) Inspection & calibration area

- Function: final check on dimension, performance, appearance.

- Core machines:

– CMM (0.8 µm + 3L/1000 accuracy)

– High-speed industrial camera (120 fps, 20 MP) + AI defect-recognition software - Auxiliary: granite surface plate (1 000 × 1 500 mm, grade 00), constant-climate room (20 °C ±1 °C, 50 %RH ±5 %).

6) Packaging & shipping area

- Function: bagging, cartoning, palletising.

- Core machines:

– Case-erecting–packing–sealing monobloc (12 cartons/min)

– On-line weigher & labeller (±10 g)

– Robot palletiser (1 200 cycles/h, 2 m reach) - Auxiliary: stretch wrapper, automatic strapping machine, LED board (shows order completion rate in real time).

7) Workshop-wide utility & environmental facilities

- Compressed air: screw compressor (22 kW, 1.3 Nm³/min, VSD) + refrigerated dryer + 3-stage filtration, dew-point ≤3 °C.

- Process vacuum: rotary vane pump (100 m³/h, ultimate 0.5 mbar) for suction/handling.

- Nitrogen: PSA generator (99.9 %, 20 Nm³/h) for explosion-proof cabinets/soldering.

- Water: process chiller (ΔT = 5 °C, 15 kW), closed loop; oil wastewater passes oil interceptor + DAF before discharge.

- HVAC & cleanroom: make-up air unit (MAU) + FFU ceiling, 15–20 ACH, 22 °C ±2 °C, 50 %RH ±10 %; cleanliness 10 000–1 000 class depending on product.

- Fire fighting: very-early-suction smoke detection + wet sprinkler (68 °C bulb); CO₂ flooding for explosion-proof zones.

- Power: dual-circuit supply for class-2 load; UPS (10 kVA, 5 min back-up) at critical stations.

3. Master equipment schedule (copy-paste ready)

| # | Stage | Machine / Facility | Must-have? | Key spec / parameter | Typical Qty (5 000 m² workshop) | Remarks |

|---|---|---|---|---|---|---|

| 1 | Receiving | Hydraulic dock leveler | ★ | 1.5 t, 1.1 × 2.0 m | 2 units | Dock to truck tail-lift |

| 2 | Receiving | Mobile dock ramp | ★ | 6 t, 10° incline | 1 unit | Temporary bay |

| 3 | Pre-treat | Ultrasonic cleaner | ★ | 28 kHz, 300 L | 1 set | Multi-tank |

| 4 | Pre-treat | Pass-through spray washer | ★ | 0.8 m belt width | 1 set | Degrease-rinse-blow |

| 5 | Sub-ass’y | Differential chain conveyor | ★ | 2 × speed, 24 m | 2 lines | Reversible |

| 6 | Sub-ass’y | Pneumatic torque driver | ★ | 0.5–12 N·m | 12 pcs | Angle monitoring |

| 7 | Sub-ass’y | Servo press | ★ | 5 kN, ±0.01 mm | 4 units | Force-displacement curve |

| 8 | Final | AGV feeding cart | ○ | 800 kg, mag/QR hybrid | 3 units | SLAM upgradeable |

| 9 | Final | 6-axis screw robot | ○ | ±0.02 mm | 2 sets | With vision |

| 10 | Final | Lift-rotate table | ★ | Ø1.2 m, 500 kg | 4 units | Free-angle stop |

| 11 | Inspect | CMM | ★ | 0.8 µm + 3L/1000 | 1 unit | Climate room included |

| 12 | Inspect | Industrial camera + AI | ○ | 120 fps, 20 MP | 2 sets | Cosmetic defects |

| 13 | Pack | Erect-pack-seal monobloc | ★ | 12 cartons/min | 1 set | On-line weighing opt. |

| 14 | Pack | Robot palletiser | ○ | 1 200 cycles/h | 1 set | 2 m reach |

| 15 | Utility | Screw air compressor | ★ | 22 kW, 1.3 Nm³/min | 2 units | 1 work + 1 standby |

| 16 | Utility | PSA N₂ generator | ○ | 99.9 %, 20 Nm³/h | 1 set | For soldering / Ex-proof |

| 17 | Utility | MAU air-handling unit | ★ | 15 000 m³/h | 2 sets | VFD fans |

| 18 | Utility | Fire-sprinkler system | ★ | 68 °C bulb heads | whole shop | incl. pump house |

★ = needed in most assembly plants; ○ = add later depending on complexity / budget.

4. Implementation tips

- Install all ★ items in phase-1; they cover ~80 % capacity. Add ○ items when volume ramps.

- When selecting machines, prefer tier-1 local brands (servo presses, AGVs, robots) — 30 % cheaper than imports and faster service.

- Require open protocols (OPC-UA / Modbus TCP) for every line-level machine; otherwise data-collection retro-fit will double the cost.

- Environmental & safety facilities must be designed and constructed together with production machines — recent EIA approvals demand 100 % wastewater collection and “zero temporary storage” of hazardous waste; undersized oil interceptor or waste-room area will lead to direct rejection.