What are the commonly used packaging machines in assembly line operations?

Common Packaging Equipment in Assembly Line Operations and Their Functions

| Equipment Name | Function Description |

|---|---|

| Automatic Packaging Machine | Completes a series of operations including automatic weighing, packaging, and sealing of products. |

| Case Opener | Automatically opens packaging cases in preparation for subsequent boxing operations. |

| Boxing Machine | Automatically places products into packaging cases. |

| Case Sealer | Seals packaging cases after products have been loaded. |

| Labeling Machine | Applies labels to packaging cases to identify product information. |

| Heat Shrink Machine | Applies heat shrink packaging to cases to enhance packaging stability and appearance. |

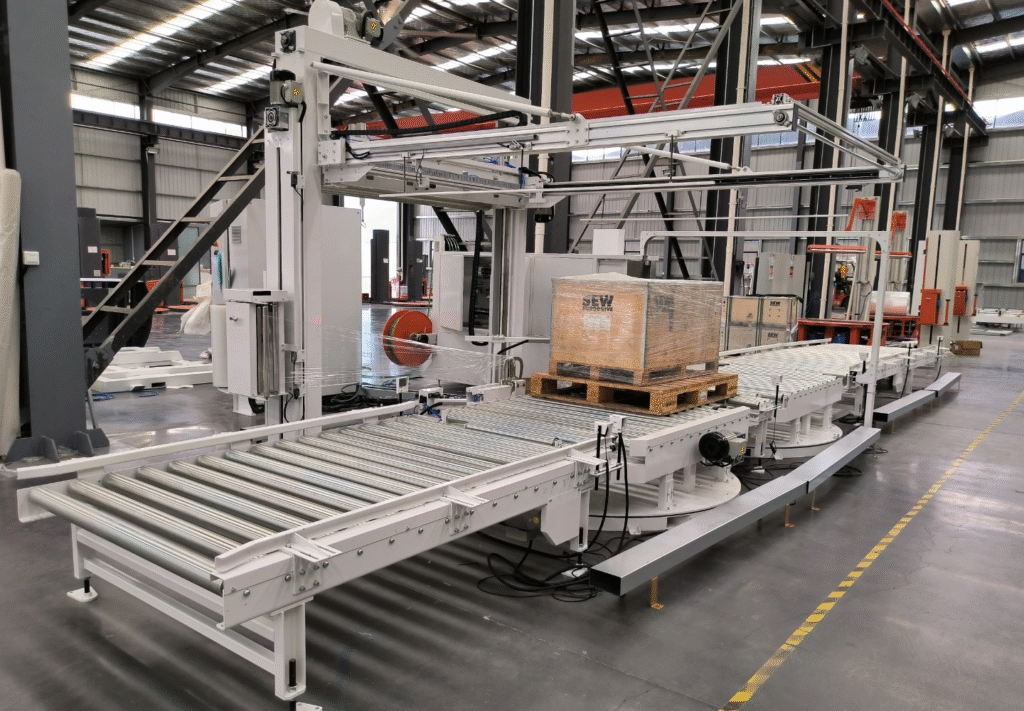

| Palletizing Robot or Palletizer | Stacks packaged products into pallets. |

| Pallet Storage and Supply Unit | Provides and stores pallets for carrying palletized stacks. |

| Stretch Wrapper | Wraps palletized stacks to prevent products from falling during transportation. |

| Automatic Coding Machine | Prints traceable codes such as production dates and batch numbers on packaging. |

Detailed Itemized Descriptions

- Automatic Packaging Machine

- Weighing Method: Options include weight-based, volume-based, and count-based weighing to suit the characteristics and packaging requirements of different products.

- Packaging Form: Supports various packaging forms such as bagging, boxing, and bottling.

- Sealing Method: Multiple sealing methods like heat sealing, adhesive sealing, and stitching ensure the seal and stability of the packaging.

- Case Opener

- Opening Method: Automatically opens packaging cases using mechanical or pneumatic devices.

- Scope of Application: Suitable for various types of packaging cases, including cardboard and plastic boxes.

- Degree of Automation: Can be integrated with conveyor systems to achieve continuous case opening operations.

- Boxing Machine

- Boxing Method: Various boxing methods such as mechanical grasping, vacuum suction, and push-in style.

- Applicable Products: Suitable for products of different shapes and sizes, such as electronic products, food, and daily necessities.

- Degree of Automation: Can be integrated with conveyor systems and case openers to achieve automatic boxing.

- Case Sealer

- Sealing Method: Multiple methods including tape sealing, hot melt adhesive sealing, and nailing.

- Scope of Application: Suitable for various types of packaging cases, including cardboard and plastic boxes.

- Degree of Automation: Can be integrated with boxing machines to achieve automatic case sealing.

- Labeling Machine

- Labeling Method: Automatic labeling with options for hot melt adhesive labeling and pressure-sensitive adhesive labeling.

- Label Type: Supports various label types including barcodes, QR codes, and text descriptions.

- Degree of Automation: Can be integrated with conveyor systems to achieve automatic labeling.

- Heat Shrink Machine

- Packaging Method: Heat shrink film packaging, suitable for a variety of products.

- Shrinking Method: Uses a hot air circulation system to make the shrink film tightly fit the product.

- Degree of Automation: Can be integrated with conveyor systems to achieve automatic packaging.

- Palletizing Robot or Palletizer

- Palletizing Method: Various methods such as mechanical arm grasping and vacuum suction cup grasping.

- Scope of Application: Suitable for products of different shapes and sizes.

- Degree of Automation: Can be integrated with conveyor systems to achieve automatic palletizing.

- Pallet Storage and Supply Unit

- Storage Method: Automatic storage and supply of pallets.

- Scope of Application: Suitable for pallets of various specifications.

- Degree of Automation: Can be integrated with palletizing robots to achieve automatic pallet supply.

- Stretch Wrapper

- Packaging Method: Automatic wrapping with options for stretch film and plastic film.

- Wrapping Method: Rotary wrapping to ensure the stability of the packaging.

- Degree of Automation: Can be integrated with conveyor systems to achieve automatic wrapping.

- Automatic Coding Machine

- Coding Method: Automatic coding with options for inkjet printing and laser marking.

- Scope of Application: Suitable for various packaging surfaces.

- Degree of Automation: Can be integrated with conveyor systems to achieve automatic coding.

These devices work together to achieve the automation, efficiency, and precision of assembly line packaging, improving production efficiency, reducing labor costs, and ensuring packaging quality and product stability.