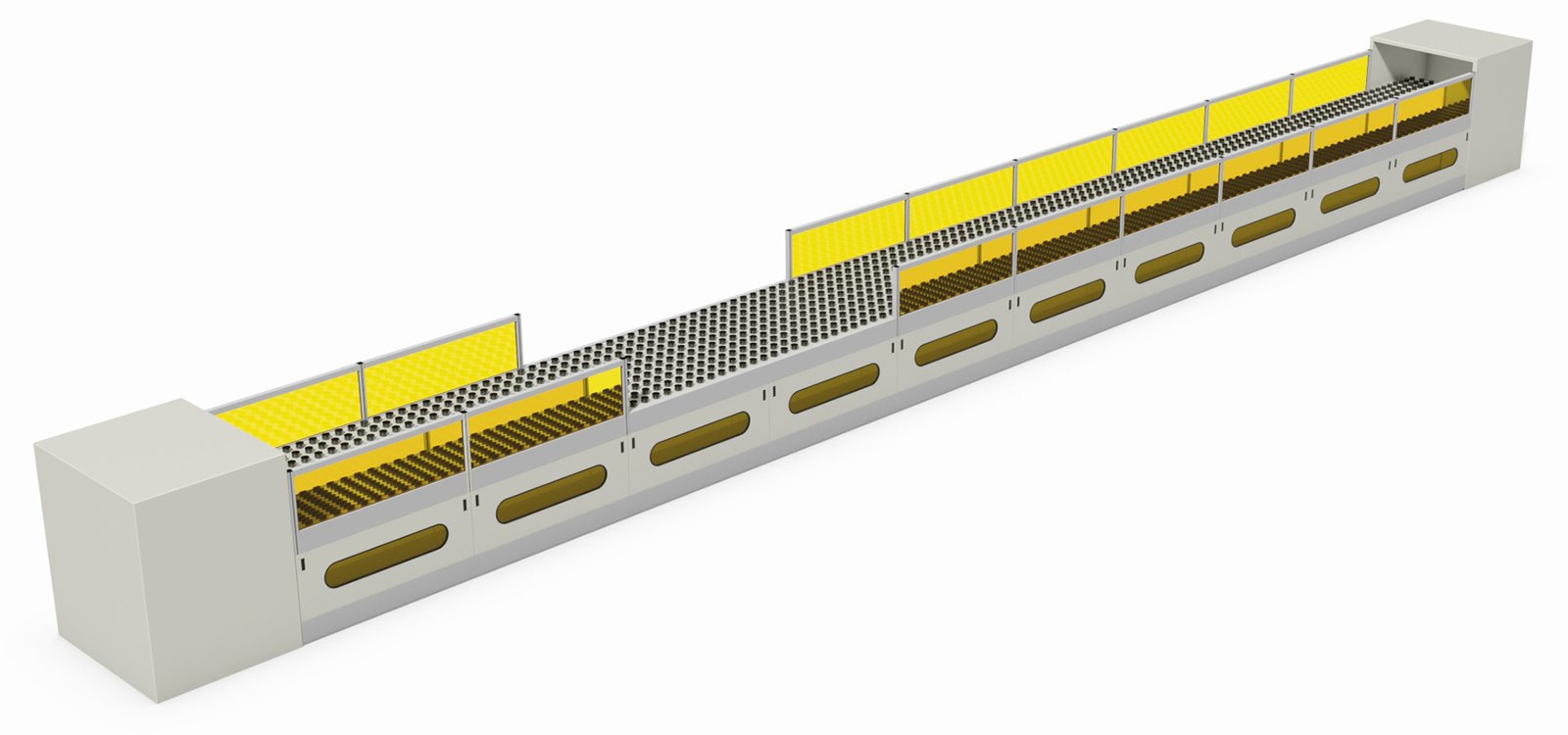

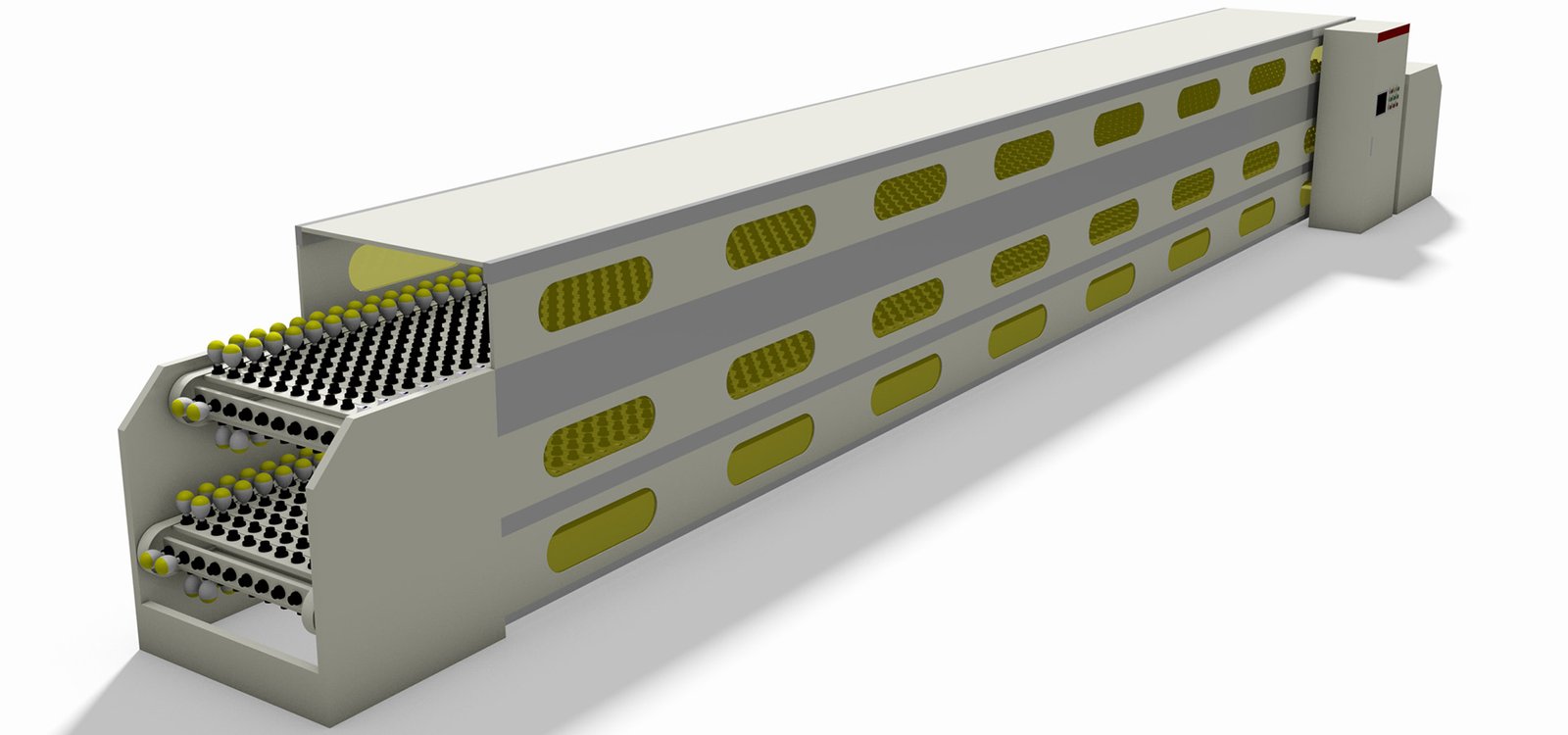

LED light aging testing conveyor line plant

LED light testing conveyor lines in industrial production are used to carry out a series of critical steps, from raw material testing, automated assembly, performance testing, burn-in testing, quality control to final packaging, ensuring the quality and performance of LED lighting products meet standards.

LED light testing conveyor lines are typically used in the following stages of industrial production:

- Incoming Material Testing: In the early stages of LED light production, incoming material testing lines are used to test the performance of raw materials or components to ensure they meet manufacturing standards.

- Assembly and Assembly: Complete light assembly lines are used for the automated assembly of various components of LED lights, such as cutting wires, bending wires, attaching aluminum rivets, power testing, pressing pins, dispensing glue, and attaching lens shells.

- Automatic Inspection: Automated testing equipment is used to measure different parameters of LED light sources, including photometric measurements (candela, lumens, and lux), color measurements (CIE XYZ color space, chromaticity coordinates, correlated color temperature, color rendering index, etc.), as well as geometric and optical measurements, to ensure product quality and reliability.

- Burn-in Testing: After assembly, LED lights typically undergo burn-in testing to ensure their long-term stability and performance.

- Packaging: Automated packaging production lines are used to package the tested LED lights, including automatic sealing, boxing, and coding.

- Quality Control: Throughout the production process, LED light testing conveyor lines can be integrated with information software to share production process data and product testing data for more efficient quality management.

- Illumination System: On the production line, LED lighting systems provide necessary illumination to support operators in visual inspection and precision operations.

- Environmental Adaptability Testing: LED lights may need to be tested under specific environmental conditions to ensure they can function properly in various environments.

- Optical Performance Testing: Testing the optical performance of LED lights, including beam angle, light distribution, and brightness.

- Safety Testing: Ensuring that LED lights meet safety standards, including electrical safety and photobiological safety.

These stages ensure the quality and performance of LED lights throughout the entire production process, thus meeting the needs of the market and consumers.

LED light aging testing equipment is specifically designed to simulate the performance and lifespan of LED lighting under long-term use conditions. These devices subject LED lights to continuous power supply and heating to accelerate the aging process, testing their reliability and durability. Here are some key features and applications of LED light aging testing equipment:

- Temperature Control: The equipment typically features an accurate temperature control system to simulate the operating conditions of LED lights under various ambient temperatures.

- Continuous Power Supply: Aging testing equipment can provide a continuous power supply over extended periods, simulating the continuous operation of LED lights in actual use.

- Data Logging: Many aging testing devices can record various parameters during the testing process, such as temperature, current, voltage, and brightness, for analysis.

- Automation: Automated aging testing systems can test multiple LED lights simultaneously and automatically record test results, improving testing efficiency.

- Safety Protection: The equipment usually includes protection against overheating, overcurrent, and short circuits to ensure the safety of the testing process.

- Environmental Simulation: In addition to temperature control, some aging testing equipment can also simulate other environmental factors such as humidity, vibration, and air pressure.

- Lifespan Prediction: Accelerated aging tests help predict the expected lifespan and reliability of LED lights.

- Failure Analysis: Aging tests are beneficial in identifying potential failures and defects in LED lights that may not appear until later stages.

- Quality Control: Aging testing is an essential part of the quality control process in LED light manufacturing, ensuring products meet the necessary quality standards before shipment.

- Compliance with Standards: The design and operation of aging testing equipment typically comply with relevant industry and safety standards, such as IEC, UL, or other region-specific standards.

LED light aging testing equipment is crucial for ensuring the long-term performance of LED lighting products and customer satisfaction, making it an essential tool for LED light manufacturers and quality testing laboratories.