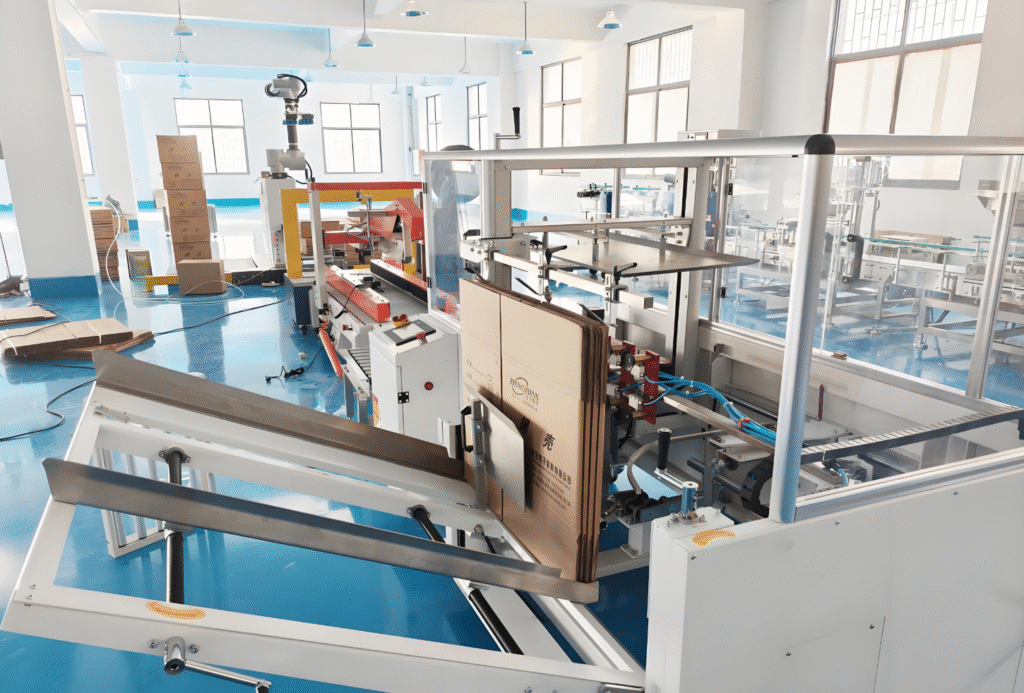

Automatic packaging and palletizing line for the end of the assembly line

The automatic packaging and palletizing line at the end of the assembly line is an important part of modern manufacturing to improve production efficiency and reduce labor costs. Below is a detailed description of the equipment composition and process flow:

Equipment Composition

- Conveyor System: Transports assembled products from the end of the assembly line to the packaging and palletizing area. Common types include chain plate conveyors and roller conveyors.

- Case Opener: Automatically opens packaging cases in preparation for the subsequent boxing operation.

- Boxing Machine: Automatically places products into the packaging cases.

- Case Sealer: Seals the packaging cases after the products have been loaded.

- Labeling Machine: Applies labels to the packaging cases to identify product information.

- Heat Shrink Machine: Applies heat shrink packaging to the cases, enhancing the stability and appearance of the packaging.

- Palletizing Robot or Palletizer: Stacks the packaged products into pallets.

- Pallet Storage and Supply Unit: Provides and stores pallets for carrying the palletized stacks.

- Stretch Wrapper: Wraps the palletized stacks to prevent products from falling during transportation.

- Control System: The automation control center of the entire line, coordinating the operation of all equipment.

Process Flow

- Product Conveying: Assembled products are transported from the end of the assembly line to the packaging area via the conveyor system.

- Case Opening and Boxing: The case opener automatically opens the packaging cases, and the boxing machine loads the products into the cases.

- Case Sealing and Labeling: The case sealer seals the loaded packaging cases, and the labeling machine applies labels to the cases.

- Heat Shrink Packaging: Heat shrink packaging is applied to the cases.

- Palletizing: The palletizing robot or palletizer stacks the packaged products into pallets.

- Pallet Supply and Stack Transfer: The pallet storage and supply unit provides pallets, and the palletized stacks are transferred onto the pallets.

- Stretch Wrapping: The palletized stacks are wrapped with stretch film.

- Stack Conveying and Storage: The completed packaged and palletized product stacks are transported to the designated storage area.

Technical Principles

- Servo Motor Motion Control: Uses servo motors to control the movement of conveyors, palletizing robots, and mixers, achieving precise positioning.

- Palletizing Robot Control Algorithms: When the packaging bag reaches the designated position on the conveyor, the palletizing robot grabs and stacks the bags according to the pre-set program.

- Quality Inspection and Rejection: After boxing, the packaging bags are weighed to check their quality.

The entire automatic packaging and palletizing line operates through the control system to achieve automated operation, improving production efficiency, reducing labor costs, and ensuring the quality of packaging and the stability of the palletized stacks.