Reference Guide for Heat Pump Water Heater/Hot Water Boiler Assembly Line

A heat-pump water heater integrates compressor, evaporator, condenser and insulated tank. On the automated slat conveyor, robots fit these parts, charge refrigerant and inject foam, then tighten torque-controlled bolts. Subsequent stations vacuum-test, leak-check, measure heating capacity, COP, electrical safety and noise. Vision systems verify labels and welds. Finished units slide into corner-protected cartons, film-bagged, palletised and shrink-wrapped. MES tracks every serial number, schedules takt, stores test data and feeds ERP, giving full traceability and paperless quality control.

I. Structure of a Heat-Pump Water Heater

A heat-pump water heater is mainly composed of the following core parts:

- Heat-Pump System (refrigeration cycle):

- Compressor: compresses low-temperature, low-pressure refrigerant vapor into high-temperature, high-pressure gas.

- Condenser: releases heat to warm the water.

- Evaporator: absorbs heat from ambient air.

- Expansion Valve: reduces refrigerant temperature and pressure to complete the cycle.

- Water-Tank System:

- Inner tank: stores hot water, usually made of stainless steel or enamel-coated steel.

- Insulation layer: polyurethane foam to minimize heat loss.

- Outer shell: protects internal components and provides an aesthetic finish.

- Heat-exchange coil / condenser: transfers heat to the water inside the tank.

- Control System:

- Includes thermostats, sensors, main control board, etc., enabling automatic operation and protection functions.

- Auxiliary Components:

- Refrigerant piping, water pump, fan, filter drier, etc.

II. Assembly Process

Typical assembly steps are:

- Tank fabrication & hole punching: create openings for refrigerant pipes, water inlet/outlet, etc.

- Heat-exchanger installation: insert condenser or coil into the tank and seal to end-caps.

- Foam insulation: inject polyurethane foam between the inner tank and outer shell.

- Heat-pump unit mounting: install compressor, evaporator, expansion valve, and connect refrigerant lines.

- Electrical wiring: connect control board, sensors, power leads, etc.

- Sealing & leak check: perform airtight tests on the refrigerant circuit.

- Performance run-test: function, performance, and safety tests.

- Cosmetic finishing & packaging.

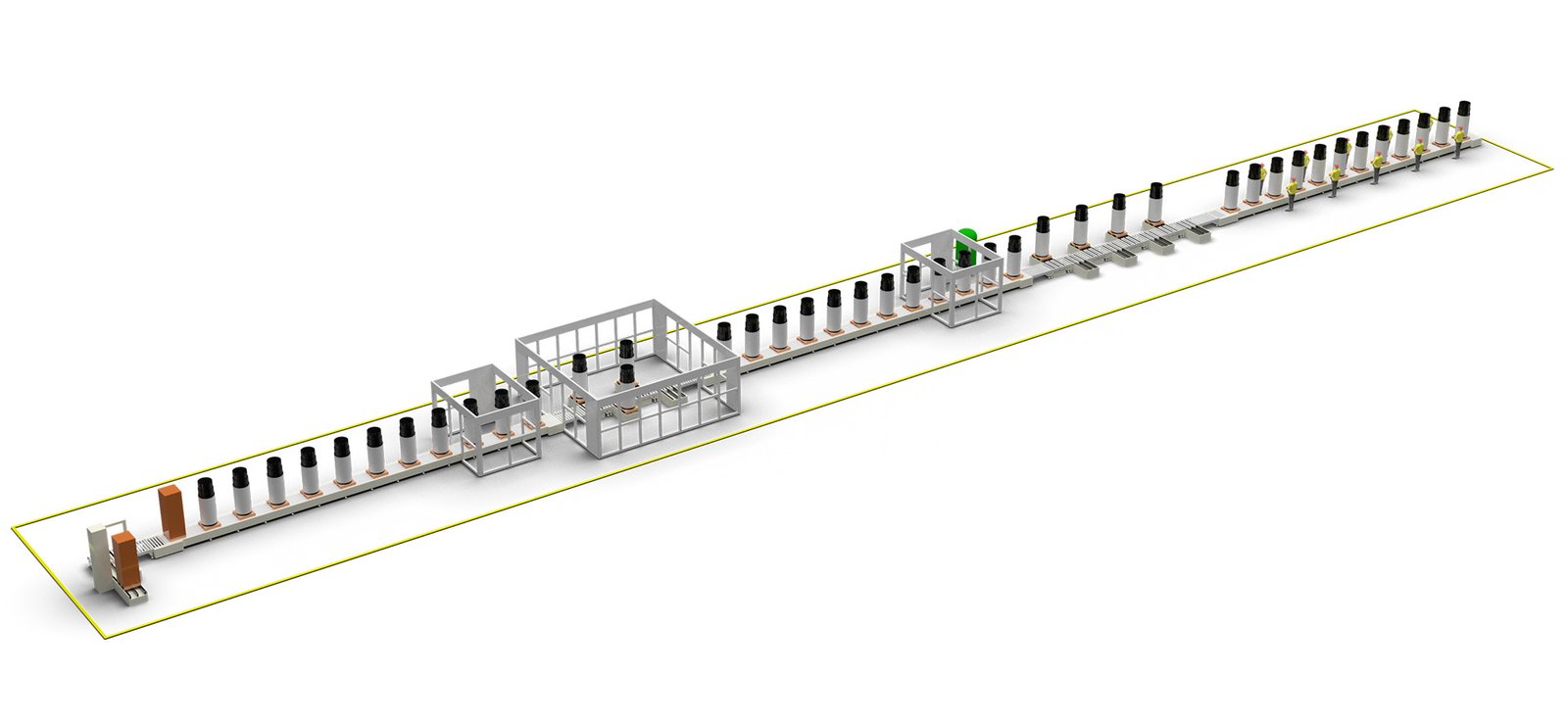

III. Assembly Line, Test Line, and Packaging Line

1. Assembly Line

- Conveyance: usually a combination of slat conveyor and roller conveyor, paced to takt time.

- Workstations: compressor mounting, refrigerant piping, electrical wiring, foam filling, etc.

- Automation equipment:

- Automatic nut-runners (torque-controlled)

- Industrial robots (handling, assembly)

- Vision systems (recognition, positioning, inspection)

- Automatic material feeding

- Jigs & fixtures (ensure accuracy)

2. Test Line

- Tests performed:

- Airtightness (helium mass-spectrometer leak test, pressure decay)

- Refrigerant charge weight check

- Performance (heating capacity, COP)

- Electrical safety (insulation, grounding, hi-pot)

- Vibration & noise

- Visual defects (scratches, dirt, labeling)

3. Packaging Line

- Packaging structure:

- Top pad, middle pad, bottom pad, corner protectors, pallet

- Bottom pad has fasteners that lock to the pallet for transport stability

- Process:

- Automatic bagging, case sealing, labeling

- Cushioning: foam, EPE, honeycomb board

- Optional automatic palletizing system

IV. MES (Manufacturing Execution System)

MES plays a key role in heat-pump water-heater production. Main functions:

- Production Planning & Scheduling:

- Adjust tasks in real time, optimize resource allocation

- Dynamically respond to order changes, reduce idle time

- Quality Management:

- Real-time collection of quality data, automatic pass/fail judgment

- Full traceability to quickly locate defective lots

- Links to test equipment to log results automatically

- Equipment Management:

- Real-time monitoring of machine status, predictive maintenance

- Fault alarms and repair-history tracking

- Increases uptime and utilization

- Traceability & Reporting:

- Every unit’s production history, materials used, and test data are traceable

- Automatic generation of production reports, quality analytics, efficiency KPIs

- Integration with Other Systems:

- Interfaces to ERP, PLM, WMS for end-to-end digital flow

- Supports barcode/RFID data capture to improve speed and accuracy

Summary

Manufacturing a heat-pump water heater is a complex process that combines thermodynamics, electrical control, and high-level automation. Modern plants integrate advanced assembly, testing, and packaging lines with a full-featured MES to achieve complete digital and intelligent management from raw material to finished goods. This not only boosts product quality and production efficiency but also provides a solid foundation for smart-manufacturing upgrades.