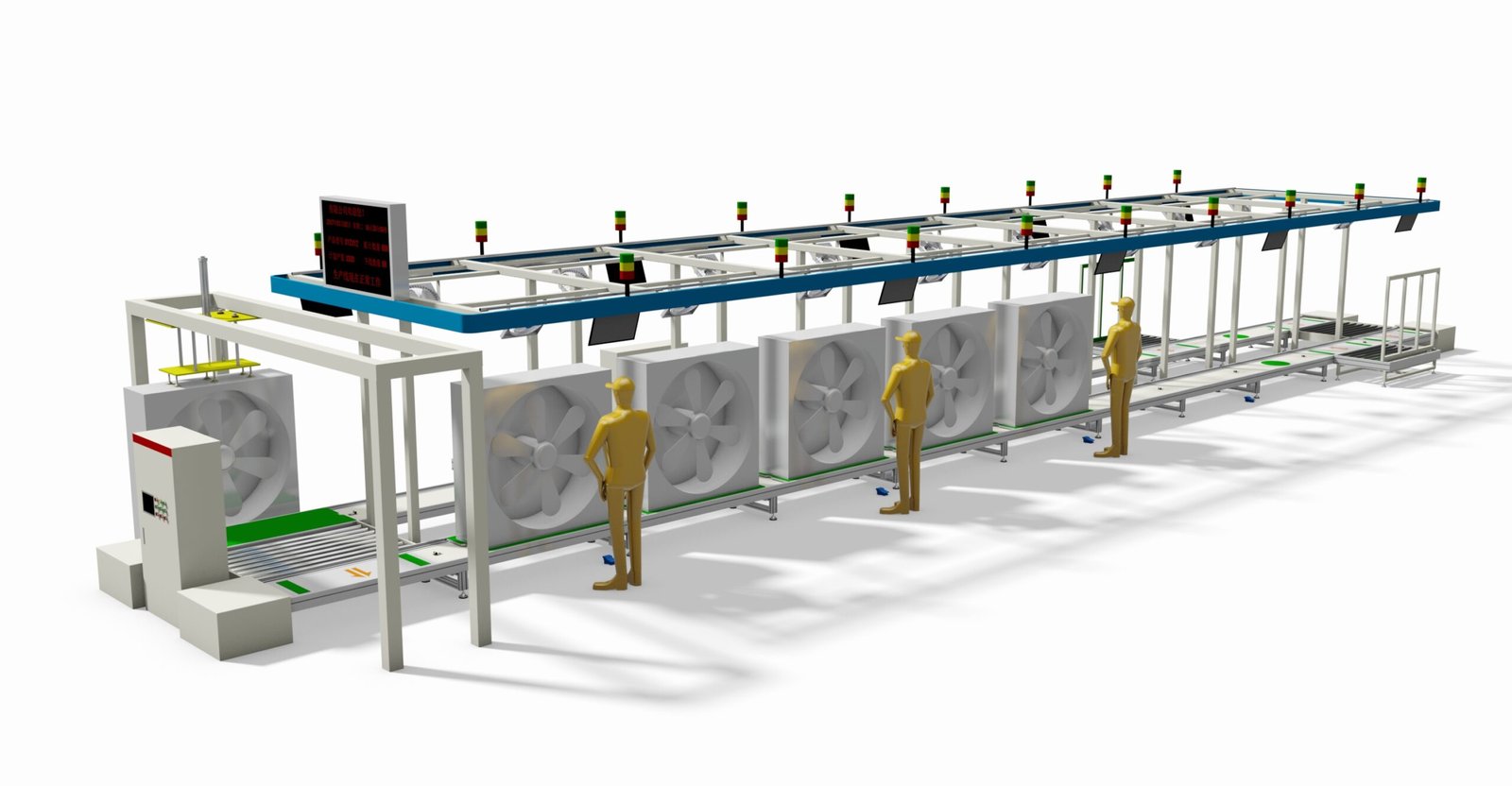

Large-airflow, low-speed agricultural fan assembly line

Based on the existing information, the technical features of large-volume low-speed agricultural fans in the three aspects of “structure–process–assembly line” can be summarized as follows:

1. Structural Features

– Blades

- Extruded hollow aluminium alloy with internal stiffening ribs: weight is reduced while rigidity is maintained.

- Straight-planform blades with identical aerofoil sections along the span.

- Leading-edge导流 zone ≈ 10 % chord

- Mid boosting zone ≈ 50 % chord, relative thickness ≥ 15 %

- Trailing-edge fairing zone ≈ 40 % chord

- Mean-camber line shaped by 4th–6th-order polynomials to secure high lift at low rpm and low noise.

- Attached to the hub by U-clamps + tie-rods + self-locking nuts, enabling 2–8-blade quick-change configurations.

– Hub & Motor

- Aerospace-grade forged-aluminium hub, light and strong.

- Direct-drive IP65 PMSM, maintenance-free, wide-speed-range high efficiency, compatible with single- or three-phase farm supply.

– Complete Unit

- Galvanised or stainless-steel casing, corrosion-resistant.

- Conical or annular spinner gives a uniform diverging jet and limits ground dust.

- Typical data: Ø up to 7.3 m, weight 70–138 kg, airflow 400 000 m³ h⁻¹, thrust 357 N.

2. Key Processes

– Blade Manufacturing

Extrusion → T4/T6 heat-treat → 5-axis machining of root fits → anodising or PVDF coating → final drilling for dynamic balance. Aerofoil tolerance ±0.2 mm.

– Hub Machining

Forged blank → 5-axis turn-mill of flow passages and bolt holes → magnetic-particle inspection → hard anodising (≥ 350 HV).

– Surface Protection

All metallic parts hot-dip galvanised or Galfan-coated, 65 µm min., guaranteeing 10-year corrosion resistance in high-NH₃ livestock houses.

– Motor Integration

Stator vacuum pressure impregnation (class-H insulation), rotor balanced to G 2.5. End-of-line 72 h full-load burn-in; overall efficiency ≥ 85 %, noise ≤ 45 dB(A).

3. Assembly-line Concept (Scheme Level)

The following “one-piece-flow + flexible station” concept is synthesised from general fan-industry practice and adjustable-fixture patents.

– Line Layout

10 stations, takt 10 min, daily output 60 units. U-shaped for easy material return. AGV + RFID pallets.

– Key Stations

- St.1 Hub pre-assembly – servo press fits bearing & locking bush, 500 N·m feedback.

- St.3 Blade positioning – quick-change convex-ring fixture handles Ø 3–7 m, blade-setting angle error ≤ 0.5°.

- St.6 Motor-to-hub marriage – cobot tightens 12 × M12 bolts to 120 N·m with torque-angle control.

- St.8 Electrical self-test – insulation, hi-pot, phase sequence, Hall signals auto-logged to MES.

- St.10 Final balancing – two-plane balancer, residual unbalance ≤ 5 g·cm, auto-drill correction.

– Quality Assurance

Critical bolts tightened by “torque + angle + yield” method; data 100 % traceable. Every fan runs 30 min @ 50 % load; vibration, current & temperature curves stored, alarms on deviation.

– Green & Safe

Rooftop PV powers lighting & test equipment; VOC capture at gluing/cleaning stations; full light-curtain guarding & e-stop, meets ISO 13849-1 PLd.

In short, large-volume low-speed agricultural fans realise high airflow, low noise and zero maintenance through “aerospace-grade hollow-aluminium blades + direct-drive PMSM + galvanised casings”. Manufacturing employs high-precision extrusion, 5-axis machining and vacuum impregnation, while assembly relies on “flexible blade fixtures + cobots + in-line balancing” to permit diameter change-over in 10 min, satisfying the farm market’s demand for high volume and reliability.