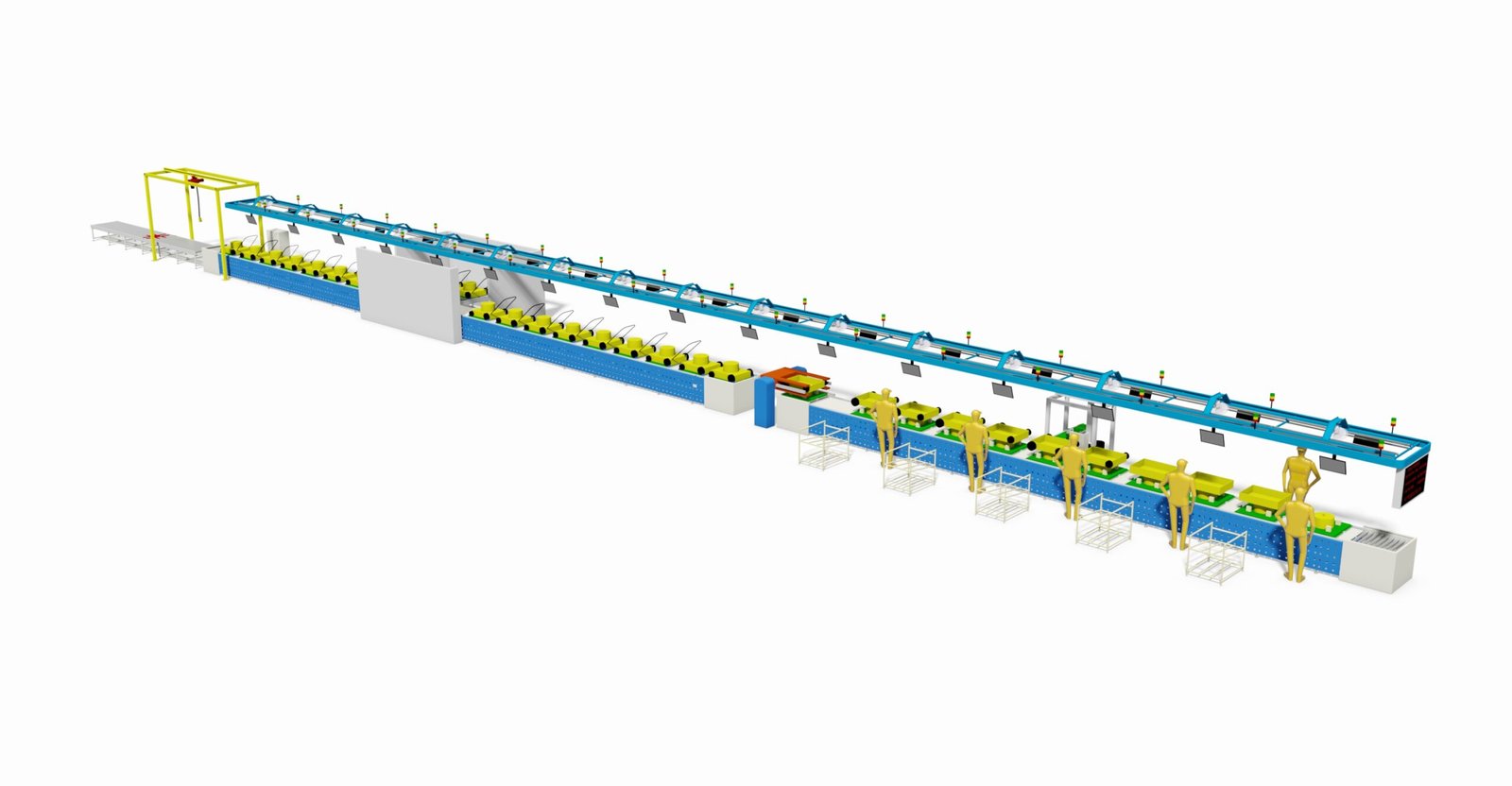

Structure and Assembly-Testing-Packaging Production Line for Gasoline Lawn Mowers

The gasoline lawn-mower line feeds 25-station differential-chain pallets through pre-assembly, engine marriage, torque-controlled drivetrain and blade fixing, then robotizes cold/hot run-in, noise, brake and grass-collection tests. Servo wrenches and RFID secure 99.5 % fastening traceability; emission and 96 dB(A) noise comply with EU Stage II. Finally an automatic erect-pack-seal unit and 6-axis palletizer deliver 10-unit, stretch-wrapped pallets at 90 s tact, giving 100 k units/year single shift with ≤0.2 % transit damage.

- Structural Modules & Key Components

1.1 Power Module

Four-stroke air-cooled gasoline engine (1E40F-3B / 168F family, 135-196 cm³, 4.5-6.5 hp) with integral fuel tank, recoil starter, diaphragm carburettor, ignition coil and flywheel brake.

1.2 Transmission & Cutting Module

Bevel gearbox (ratio ≈ 1:1, noise ≤ 85 dB(A)), steel cutter disc / swing blade (305 × 90 × 2 mm, dynamic balance ≤ 5 g·cm), optional nylon-line trimmer head, centrifugal clutch (engagement 2 800 ± 100 r/min).

1.3 Propulsion & Height-Adjustment Module

8-10 ″ front & rear wheels (maintenance-free ball bearings), 4-link + threaded hand-wheel height adjuster, 10 positions 30-80 mm.

1.4 Control & Safety Module

Adjustable U-shape handle (rubber over-mould, anti-vibration), throttle-brake interlock, 60 L quick-release plastic grass bag, flywheel brake stop < 3 s, full 360° disc guard (≥ 15 mm rigid skirt).

1.5 Frame & Cladding

Stamped steel deck (1.8 mm cold-rolled sheet, ED + powder coat), net mass 31-42 kg, overall L × W × H ≈ 1 560 × 505 × 1 025 mm.

- Assembly Line Process (tact ≤ 90 s/unit, 100-150 k units/year)

2.1 Line Configuration

Differential roller chain + pallet (800 × 600 mm, RFID), speed 0.3-1.5 m/min VFD; 25 main stations + 5 repair side-stations, pitch 2 m.

2.2 Station Breakdown & Key Operations

0# Pre-assembly (off-line)

- Engine hot run: 3 000 r/min × 10 min, oil temp 90 °C, emission pre-check.

1# Deck loading → 2# Front & rear axle / wheel shaft → 3# Height-adjuster mechanism → 4# Bevel gearbox (Loctite 243, M6 bolt 18 N·m, electronic wrench 100% data capture) → 5# Clutch & drive shaft (run-out ≤ 0.2 mm) → 6# Engine loading (60 kg assist manipulator) → 7# Throttle cable, stop wire, fuel hose (quick connector + clamp double lock) → 8# Fuel tank & carburettor (prime & leak check) → 9# Ignition coil & flywheel (air gap 0.3 ± 0.05 mm) → 10# Muffler & shield (clearance to tyre ≥ 10 mm) → 11# Control handle (symmetry ≤ 1°) → 12# Grass-bag bracket → 13# Cutter disc / trimmer head (23 N·m + 30° turn) → 14# Front & rear wheels (axle nut 35 N·m) → 15# Harness routing + protective sleeve → 16# Vision & presence check (AI camera) → 17# Transfer to test area

*Stations 3, 6, 9, 13 are safety-critical torque; 7 & 8 are fuel seal (optional helium leak).

2.3 Quality Gates - Torque pass rate ≥ 99.5 %; RFID vs BOM auto-check; line stop on miss/ wrong part.

- 2-D code of critical parts linked to serial No., data stored ≥ 10 years.

- On-line Run-in & Final Testing

3.1 Cold Run-in (3 min)

No-load 3 000 r/min × 180 s; vibration ≤ 12 mm/s, oil pressure ≥ 0.2 bar, no abnormal noise.

3.2 Hot Performance (5 min)

Step-load with hysteresis brake 25 %-100 %; measure:

- Real power, torque, fuel consumption (25 % load point);

- CO ≤ 5 g/kWh, HC ≤ 5 g/kWh (NDIR fast analyser);

- Oil temperature < 110 °C, spark plug clean.

3.3 Noise / Vibration

Hemispherical 6-point, 4 m radius, background < 45 dB(A); sound power ≤ 96 dB(A) (EU 2000/14/EC Stage II).

3.4 Brake & Safety

Flywheel brake ≤ 3 s, cutter stop < 5 s; clutch disengage speed slope logged.

3.5 Grass Collection Test

30 m² artificial turf, 40 mm cut height, 2 passes; collection rate ≥ 95 %, no striping.

3.6 Final Judgement

All data auto-upload to MES; failed units to repair loop; passed units get 3-year warranty label (one code per unit).

- Packaging & Palletising Line

4.1 Pre-packaging

Drain hot oil → refill to upper level → blow off grass → apply 8 warning / compliance labels (fuel grade, cutter, exhaust, muffler, maintenance, CE, noise, barcode).

4.2 Case Erecting, Bag Insertion, Packing

- Auto case erector: 3-ply carton 1 150 × 510 × 510 mm, bottom U-shape corner + honeycomb pad;

- Bag inserter: 0.08 mm PE bag + 2 desiccant packs;

- Unit lowered into carton, clamped by 2 EPS end-caps, top 5-layer honeycomb;

- Accessory pack: manual, warranty card, tool roll (spark-plug socket, 8-10 spanner, oil funnel).

4.3 Sealing & Labelling

Auto top flap + hot-melt glue; weight check 31 ± 0.5 kg; logistic & CE labels.

4.4 Robot Palletising

1 × 1 m pallet, 5 layers × 2 = 10 units/pallet, stretch wrap + corner board, into WMS.

4.5 Throughput Match

Packing tact ≤ 75 s/case; matches main line 15 units/h; OEE ≥ 85 %.

- Key Equipment List (100 k units/year, single shift)

1 Differential chain main line (25 stations, pallets + RFID)

12 Servo torque wrenches (Atlas Copco or Desoutter)

2 Assist manipulators (engine & tank loading)

2 Cold + 2 Hot test benches (4-unit parallel)

1 Hemi-anechoic noise room (6-mic array)

1 Auto erect-pack-seal unit

1 6-axis palletising robot (ABB -120 kg payload)

1 MES + Andon + full traceability system

- Common Issues & Improvement Levers

Issue 1: Carburettor prime slow → add “vacuum pre-fuel” jig at station 8, cut first-start time by 20 s.

Issue 2: Disc high-speed jitter → integrate “dynamic balance + weight” station, one-shot correction, 60 % less rework.

Issue 3: Noise overshoot → double-perforated inner pipe + glass wool inside muffler, −3 dB(A) average.

Issue 4: Transit carton failure → add 5 mm bottom honeycomb + cross corner board, damage rate down from 1.2 % to 0.2 %.

By linking the above five process blocks and three systems, a single-shift 100 k-unit-per-year gasoline lawn-mower plant can run with high efficiency, full traceability and consistent quality, meeting EU Stage-II emission and CE safety directives. The scheme is ready for green-field or retrofit implementation.